Time to ditch

the spreadsheets

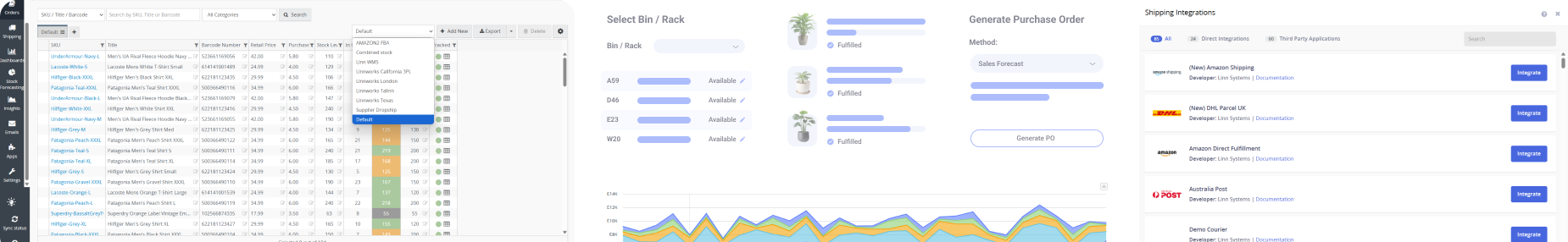

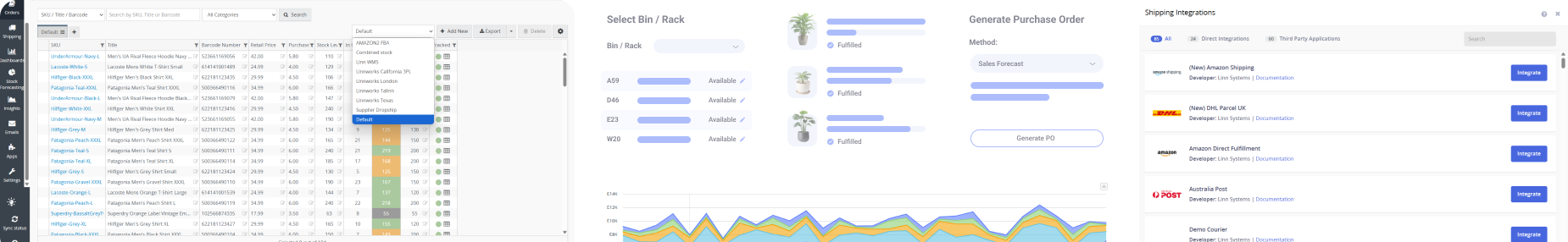

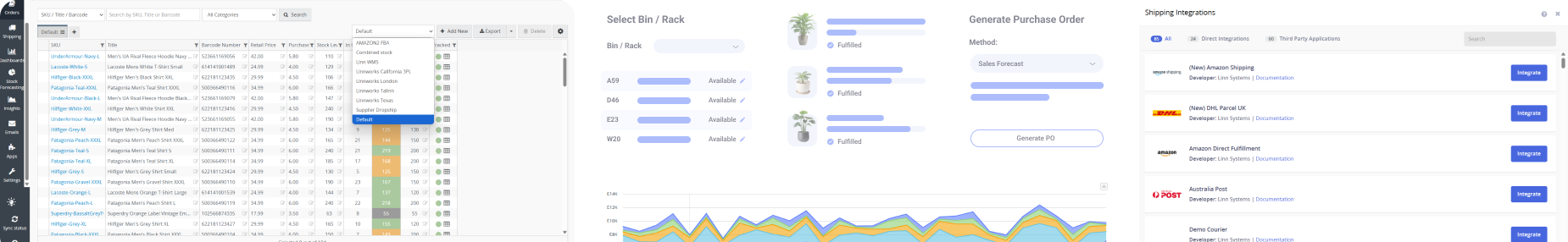

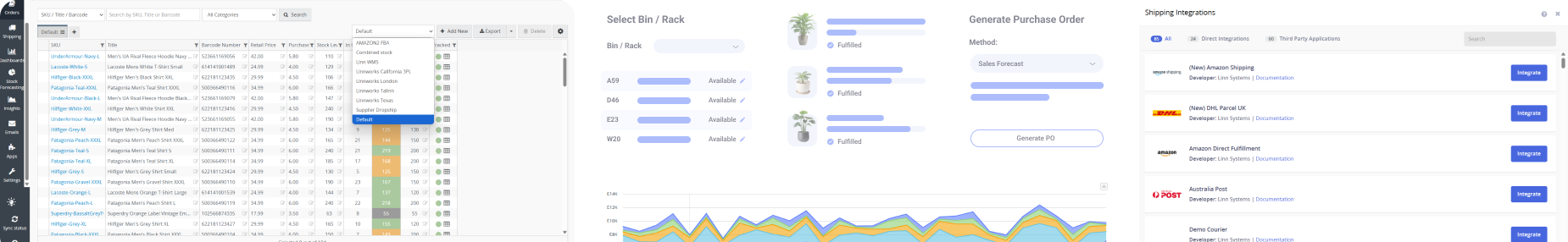

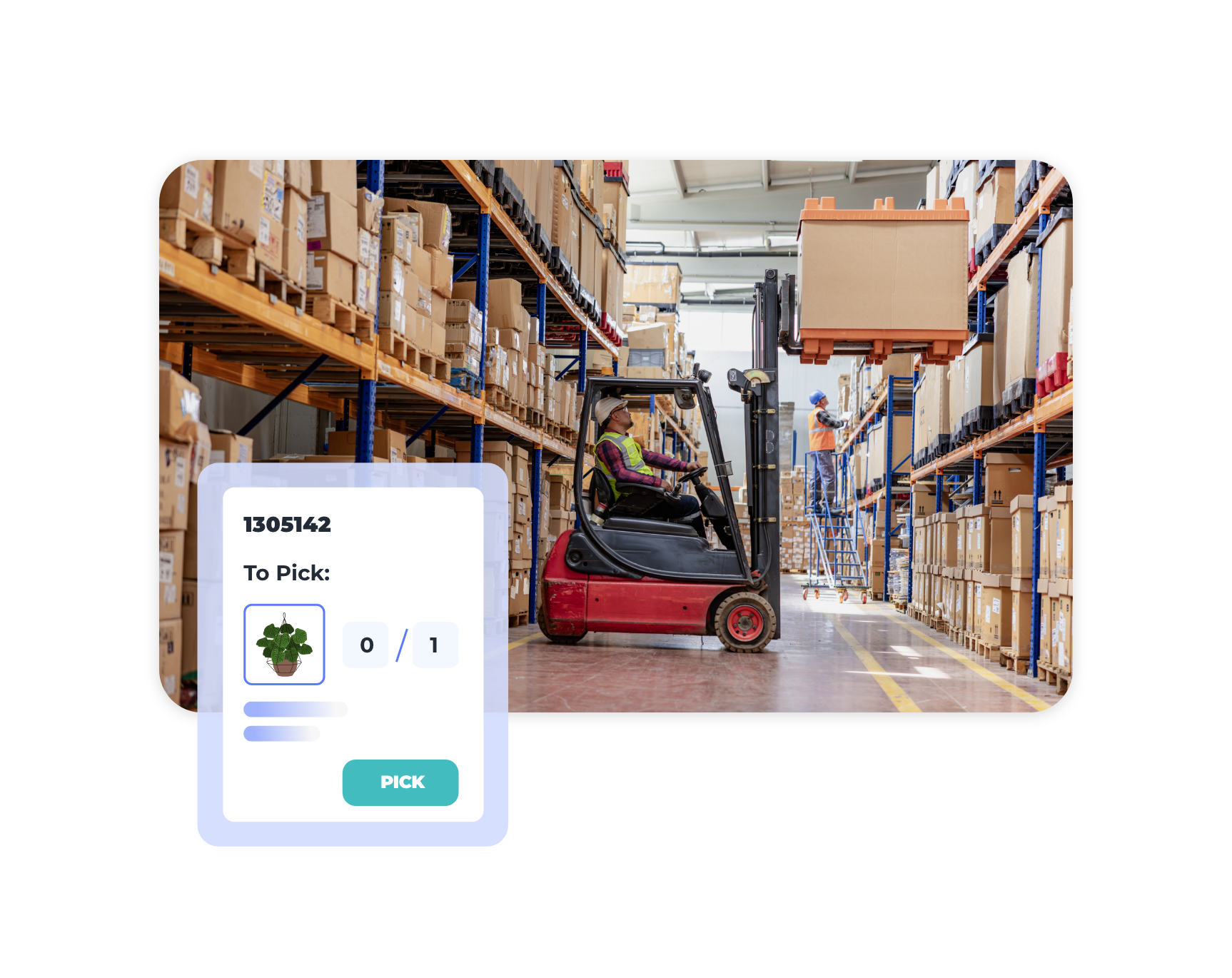

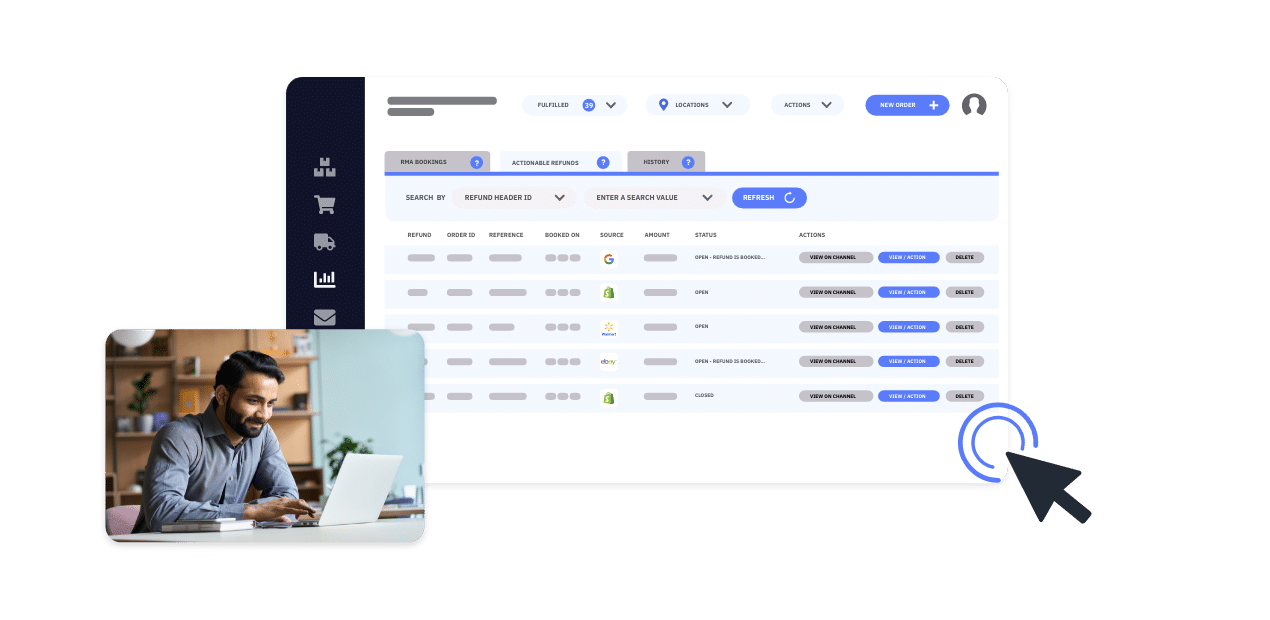

Upgrade to a true all-in-one digital platform for easier, more organized warehouse management. Automatically-generate digital picklists for faster fulfillment, higher staff efficiency and happier customers.

Testimonials

Inventory and warehouse management savings calculator

Uncover the cost of your mis-ships, out of stocks and lack of labor efficiency with our inventory management savings calculator.

Warehouse management FAQs

Get answers to our most asked questions about our plans

Warehouse management functionality is available as an add-on to Linnworks Advanced. SkuVault Core also has an add-on called enhanced warehouse. For more information, please visit our pricing page.

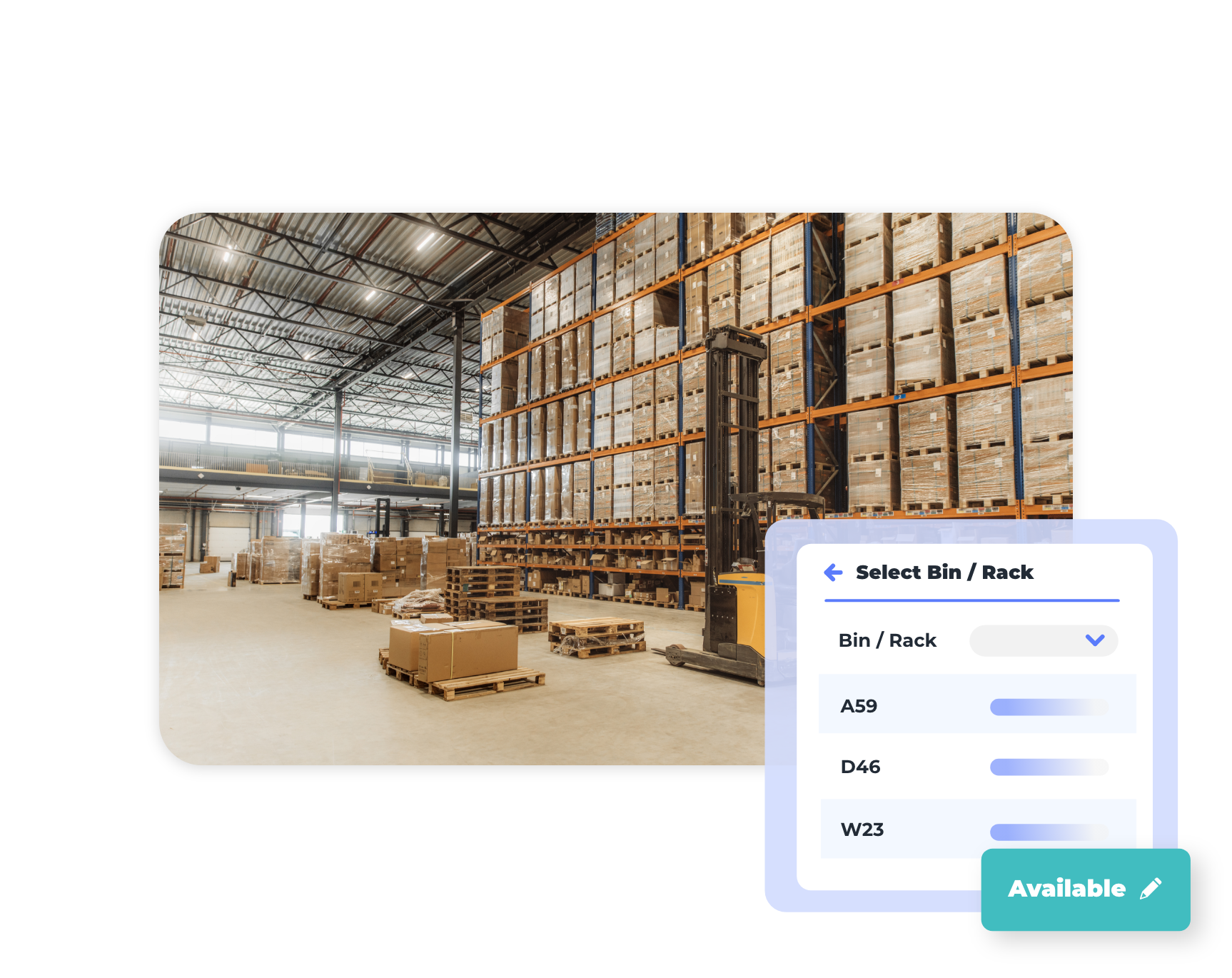

Yes, Linnworks Advanced has a feature called Default stock availability. This setting allows you to assign batch status to the stock based on the type of binrack that the stock is being put in. For example, you have binracks with a bin type called Deep Storage. Deep Storage binracks have the Default stock availability set to Restricted, meaning the stock in these binracks will not be advertised for sale on the channel. The description of the three options is below:

- Unchanged: All bin types will have the Default stock availability set to Unchanged until it is changed manually by the user. This is the default state of all bin types.

- Available: The stock stored in such binracks can be used to fulfill orders.

- Restricted: The stock is restricted to be used to fulfill orders. For example, deep storage, returned, scrapped, quarantined stock, etc.

SkuVault has three different types of locations – Picking, Backstock, and Reserved. By default, items stored in a Reserved location are not advertised for sale on any channel.

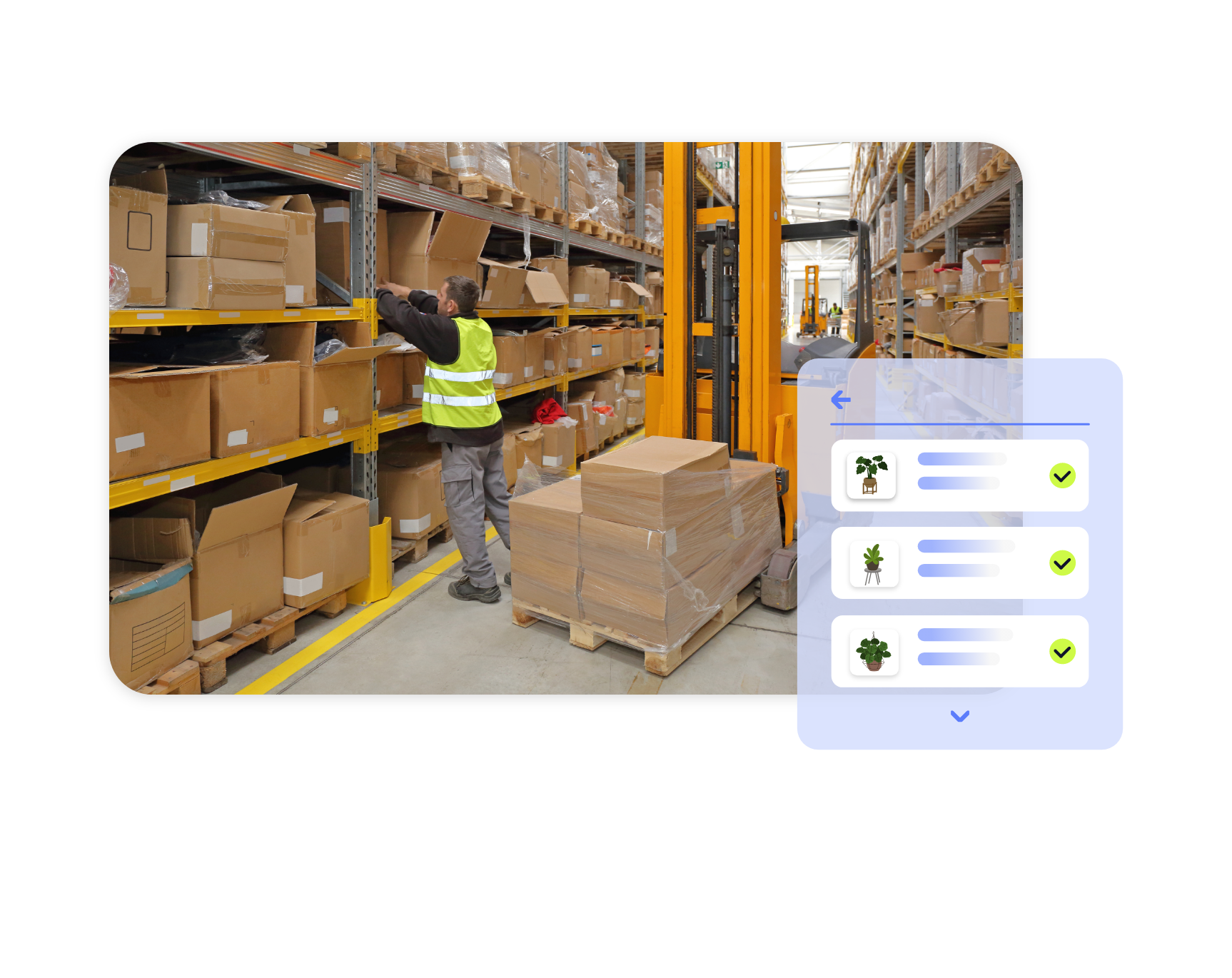

Yes, Linnworks Advanced has a feature called pickwaves and SkuVault Enhanced Warehouse has Wavepicking. These are a digital picklist of items available for selection and allows warehouse workers to quickly and efficiently find and pick the correct items.

SkuVault Core has a feature called Move/Merge which allows inventory to be transferred between warehouses and locations seamlessly. Each of these movements are tracked down to the user and can be viewed in our Transaction History report.

Warehouse management functionality is available as an add-on to Linnworks Advanced. SkuVault Core also has an add-on called enhanced warehouse. For more information, please visit our pricing page.

Yes, Linnworks Advanced has a feature called Default stock availability. This setting allows you to assign batch status to the stock based on the type of binrack that the stock is being put in. For example, you have binracks with a bin type called Deep Storage. Deep Storage binracks have the Default stock availability set to Restricted, meaning the stock in these binracks will not be advertised for sale on the channel. The description of the three options is below:

- Unchanged: All bin types will have the Default stock availability set to Unchanged until it is changed manually by the user. This is the default state of all bin types.

- Available: The stock stored in such binracks can be used to fulfill orders.

- Restricted: The stock is restricted to be used to fulfill orders. For example, deep storage, returned, scrapped, quarantined stock, etc.

SkuVault has three different types of locations – Picking, Backstock, and Reserved. By default, items stored in a Reserved location are not advertised for sale on any channel.

Yes, Linnworks Advanced has a feature called pickwaves and SkuVault Enhanced Warehouse has Wavepicking. These are a digital picklist of items available for selection and allows warehouse workers to quickly and efficiently find and pick the correct items.

SkuVault Core has a feature called Move/Merge which allows inventory to be transferred between warehouses and locations seamlessly. Each of these movements are tracked down to the user and can be viewed in our Transaction History report.

RESOURCES

or find your next opportunity

Find your next marketplace quiz

Take our quick quiz to get personalized recommendations based on your goals, product types, and target audience.

Linnworks Advanced

product tour

Sync inventory, create listings on the top marketplaces, automate fulfillment routing, and lots more with Linnworks Advanced, the all-in-one IMS platform for multichannel retailers.

Linnworks demo: connected ecommerce for established retailers & brands

Optimize your ecommerce tech stack to eliminate inefficiencies and streamline your online selling process.

Ready to

Click the button below to request a specialist that can walk you through the Linnworks platform and unify your ecommerce operation.