Simpler warehouse operations

Welcome to the gold standard of warehouse management – with faster fulfillment, greater inventory accuracy, and 85+ shipping integrations to choose from.

Boost inventory accuracy to keep your operations running smoothly and customers satisfied.

Elevate your work efficiency – accomplish more in less time with Linnworks.

Put tedious manual tasks on autopilot, freeing up your valuable time for more strategic tasks.

Stay ahead of the curve, ready to scale up instantly as your business grows.

Support your shipping team by streamlining their processes, helping them pick more orders without extra work.

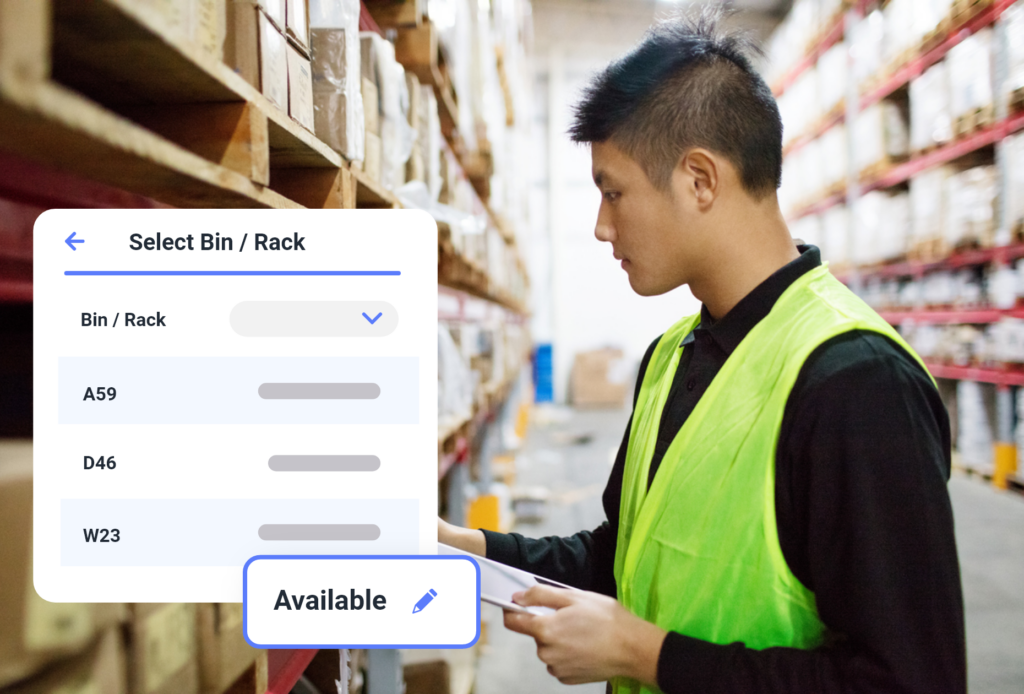

Make every shelf count

No more restrictions to one SKU per bin rack. Our system allows you to store similar SKUs across multiple bin racks, giving you the flexibility to manage your inventory your way.

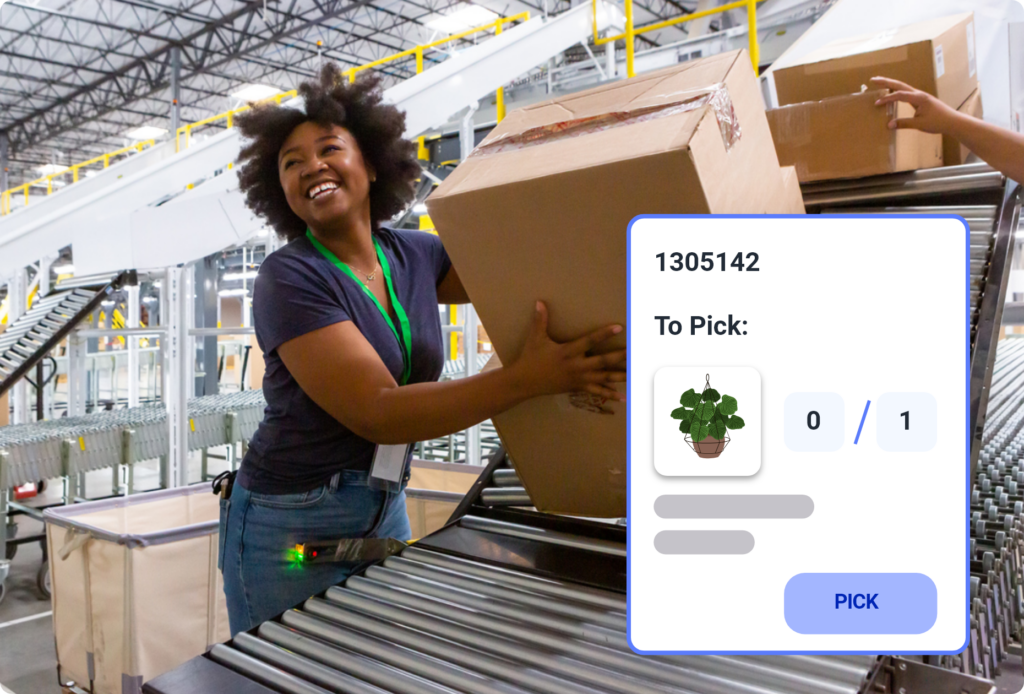

Ship faster with digital picklists

Make warehouse staff happy – and customers even happier – with automated picklists showing the most efficient route to fulfill orders.

Ready, steady, scale

Need to optimize for space? We’ve got you. Map every zone, group and bin type to delegate better and adapt for higher demand.

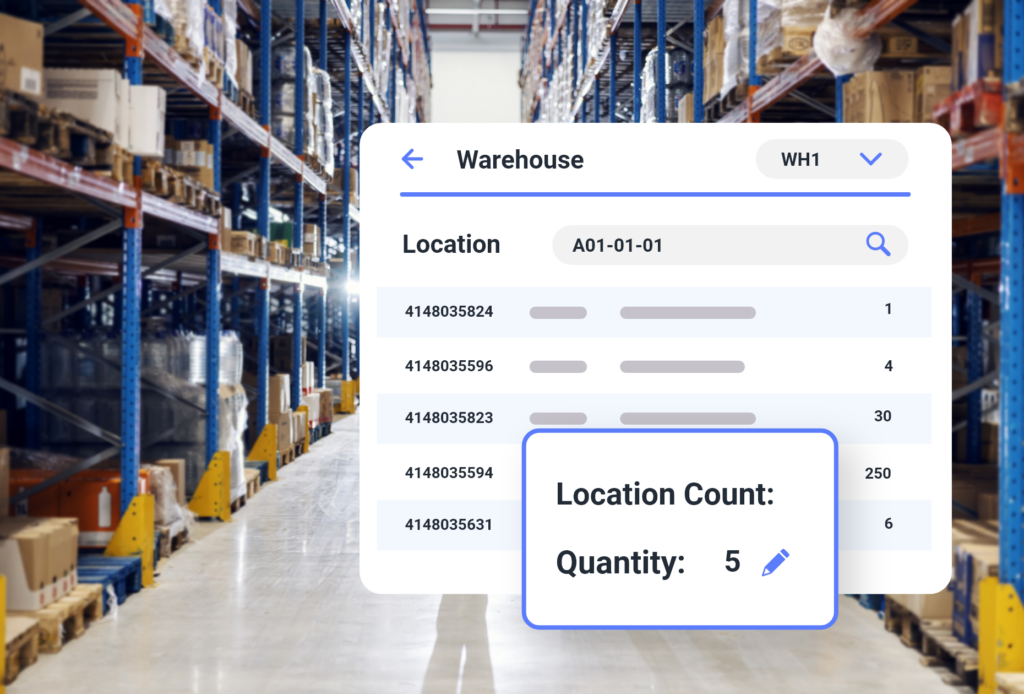

Track every item, from shelf to shipping

There’s a reason warehouse & ops managers rate Linnworks as the best warehouse management software on G2: barcode scans and stock counts give them confidence that every product is where it should be.

FAQs

Warehouse management functionality is available as an add-on to Linnworks Advanced. SkuVault Core also has an add-on called enhanced warehouse. For more information, please visit our pricing page.

Yes, Linnworks Advanced has a feature called Default stock availability. This setting allows you to assign batch status to the stock based on the type of binrack that the stock is being put in. For example, you have binracks with a bin type called Deep Storage. Deep Storage binracks have the Default stock availability set to Restricted, meaning the stock in these binracks will not be advertised for sale on the channel. The description of the three options is below:

- Unchanged: All bin types will have the Default stock availability set to Unchanged until it is changed manually by the user. This is the default state of all bin types.

- Available: The stock stored in such binracks can be used to fulfill orders.

- Restricted: The stock is restricted to be used to fulfill orders. For example, deep storage, returned, scrapped, quarantined stock, etc.

SkuVault has three different types of locations – Picking, Backstock, and Reserved. By default, items stored in a Reserved location are not advertised for sale on any channel.

Yes, Linnworks Advanced has a feature called pickwaves and SkuVault Enhanced Warehouse has Wavepicking. These are a digital picklist of items available for selection and allows warehouse workers to quickly and efficiently find and pick the correct items.

SkuVault Core has a feature called Move/Merge which allows inventory to be transferred between warehouses and locations seamlessly. Each of these movements are tracked down to the user and can be viewed in our Transaction History report.

FAQs

Warehouse management functionality is available as an add-on to Linnworks One. For more information, please visit our pricing page.

Yes, Linnworks has a feature called Default stock availability. This setting allows you to assign batch status to the stock based on the type of binrack that the stock is being put in. For example, you have binracks with a bin type called Quarantine. Quarantine binracks have the Default stock availability set to Restricted, meaning the stock in these binracks will not be advertised for sale on the channel. The description of the three options is below:

- Unchanged: All bin types will have the Default stock availability set to Unchanged until it is changed manually by the user. This is the default state of all bin types.

- Available: The stock stored in such binracks will be included in figures used to advertise on sales channels.

- Restricted: The stock is restricted to be used to fulfill orders. For example, deep storage, returned, scrapped, quarantined stock, etc.

Yes, you can define routing sequence numbers on a BinRack to tell your pickers how to prioritize their picking route.