Ecommerce inventory management: 15 top techniques and best practices

As the digital marketplace continues to grow and diversify, effectively managing your inventory has become more crucial than ever. Whether you’re a budding entrepreneur launching your first online store or a seasoned veteran looking to optimize your operations, understanding the ins and outs of ecommerce inventory management can be the difference between business success and a logistical nightmare, especially when it comes to maintaining inventory levels and efficient management processes.

Outdated or inefficient inventory management practices can quickly lead to missed opportunities, customer dissatisfaction, and diminished profits. Strong inventory control and taking measures to control excess inventory are essential steps to avoid these pitfalls.

In this comprehensive blog post, we’re going to share with you 15 top techniques and best practices for ecommerce inventory management.

In this post, we’ll unpack:

- The differences between techniques and best practices

- The pros and cons of the most popular inventory methodologies

- The role ecommerce inventory management software plays in your success

- How technology can streamline your warehousing workflows

By the end, you’ll have a clear path forward on how to optimize every facet of your ecommerce inventory management, from accurate inventory data to supply chain management and inventory forecasting.

15 ecommerce inventory management techniques and best practices

1. Just-in-time (JIT) inventory management

As the name implies, businesses that utilize this inventory philosophy stock a product each time a customer orders it, such that the volume of inventory is more or less equal to the number of filled orders. This approach aligns inventory movement directly with customer demand.

The JIT method was perfected by Toyota and its car manufacturing process. It goes without saying that while it affords significant capital savings, this technique is risky.

Just-In-Time (JIT) inventory management can fail due to disruptions like natural disasters, labor strikes, supplier unreliability, or sudden demand surges, all of which can halt production and dramatically impact inventory operations.

Moreover, issues like poor quality control, reliance on technology, and geopolitical changes can also negatively affect JIT systems, leading to increased costs or compromised product quality.

Despite potential pitfalls, JIT inventory management is often considered one of the best inventory management methodologies due to its ability to significantly reduce storage costs, improve cash flow, and enhance operational efficiency by minimizing waste.

It also fosters stronger supplier relationships and, through constant inventory turnover, ensures the quality and relevancy of goods, leading to improved customer satisfaction.

Advantages

- No risk of revenue tied up in dead stock

- Easier to manage and track inventory in your warehouse

- Less space needed to house products — a smaller warehouse means lower storage costs

Disadvantages

- Heavily reliant upon buying trends — unexpected surges in demand can cause stock-outs

- Difficult to sustain with growth, multiple warehouses, or lots of product types

2. First in, first out (FIFO) inventory management

First in, first out (FIFO) means the first products your warehouse receives are the first to be shipped out to the end users.

FIFO supports optimal inventory levels by keeping older products moving first.

This inventory tracking strategy is mostly implemented in food service or food supply industries where businesses are dealing with perishable items.

However, any business can implement FIFO, especially if they don’t want to house products for longer than necessary or want to prevent inventory shrinkage.

FIFO will not be an appropriate strategy if the materials or goods purchased have fluctuating price patterns. This can cause discrepancies between the cost of goods received and the costs of goods sold.

Advantages

- Less waste, especially when dealing with perishable items

- Optimized warehouse circulation — no product is stored for longer than necessary

Disadvantages

- Can result in inflated profits if production costs fluctuate

State of your commerce quiz

How do your ecommerce operations stack up? Take our quiz to see where you stand and get actionable next steps to improve your workflows.

3. Dropshipping

Dropshipping could very well be named the “anti-inventory” inventory management solution. The whole idea is that you, the business owner, never touch the product, eliminating the need for physical inventory count or operations on-site.

Once a customer places an order, you fulfill it from the manufacturer and send it straight to them. Thus, dropshipping completely cuts out the middleman and traditional inventory management processes.

This is helpful for business owners who are trying to break into ecommerce but can’t yet justify the cost of a warehouse or storage space. We wrote a blog post with ideas for products to dropship to help you get started.

However, there’s no such thing as a free lunch, and these “shortcuts” come at a cost.

Manufacturers have an incentive to give discounts and bonuses to businesses that buy and store their products in bulk. After all, once the product is shipped to a warehouse, the business owner now shoulders the burden of getting it sold.

That incentive is gone with dropshipping, which almost always means higher fulfillment costs. Some business owners simply don’t have a choice. They’re willing to eat the higher costs to get their foot in the ecommerce door.

Another challenge with dropshipping is the complete lack of control you have over the customer experience, customer order handling, and overall order management. Since you’re not physically overseeing how the stored product gets to the end user, you’re completely dependent upon the manufacturer.

Advantages

- Eliminates the need for small businesses to purchase warehouse space

- An approachable introduction to the world of ecommerce

Disadvantages

- Total lack of visibility and quality control

- Higher fulfillment costs

4. 3PL fulfillment

Third-party logistics (abbreviated as 3PL) is the practice of businesses handling eCommerce logistics for other businesses.

For an agreed-upon fee, 3PL providers will handle basic logistics for eCommerce clients, including (but not limited to) inventory management, warehousing, and fulfillment.

Each 3PL vendor varies in its offerings, expertise, and ability to accommodate more complex supply chain management tasks.

3PL is appealing to business owners who fancy themselves more visionaries than detail-oriented people. They’re more than willing to pay a premium to get their precious time back.

If that sounds like you, check out our deep-dive on 3PL warehouse fulfillment logistics to see if your ecommerce business can benefit from it.

Advantages

- Substantial cost savings on warehouse rent, employees, and shipping materials

- Access to massive warehousing infrastructures which open up new customer bases

- Affords business leaders a surplus of time to focus on high-level tasks

Disadvantages

- Physical distance from products means less control over quality assurance and branding

- Products that require complex kitting or assembly may not be eligible

- Many 3PL vendors require an upfront investment

Mastering 3PL: the ultimate guide to third-party logistics

Explore the benefits of third-party logistics and learn how it can enhance your ecommerce operations effectively.

5. Forecast future demand by studying historical data

Once you’ve decided on an inventory management strategy and assessed the current demand for your products, it’s time to do some predictive analytics. This is one of the most essential inventory management best practices because it helps prevent overstock and understock situations.

As a general rule in all disciplines of business, a successful organization is one that makes the future a little less uncertain.

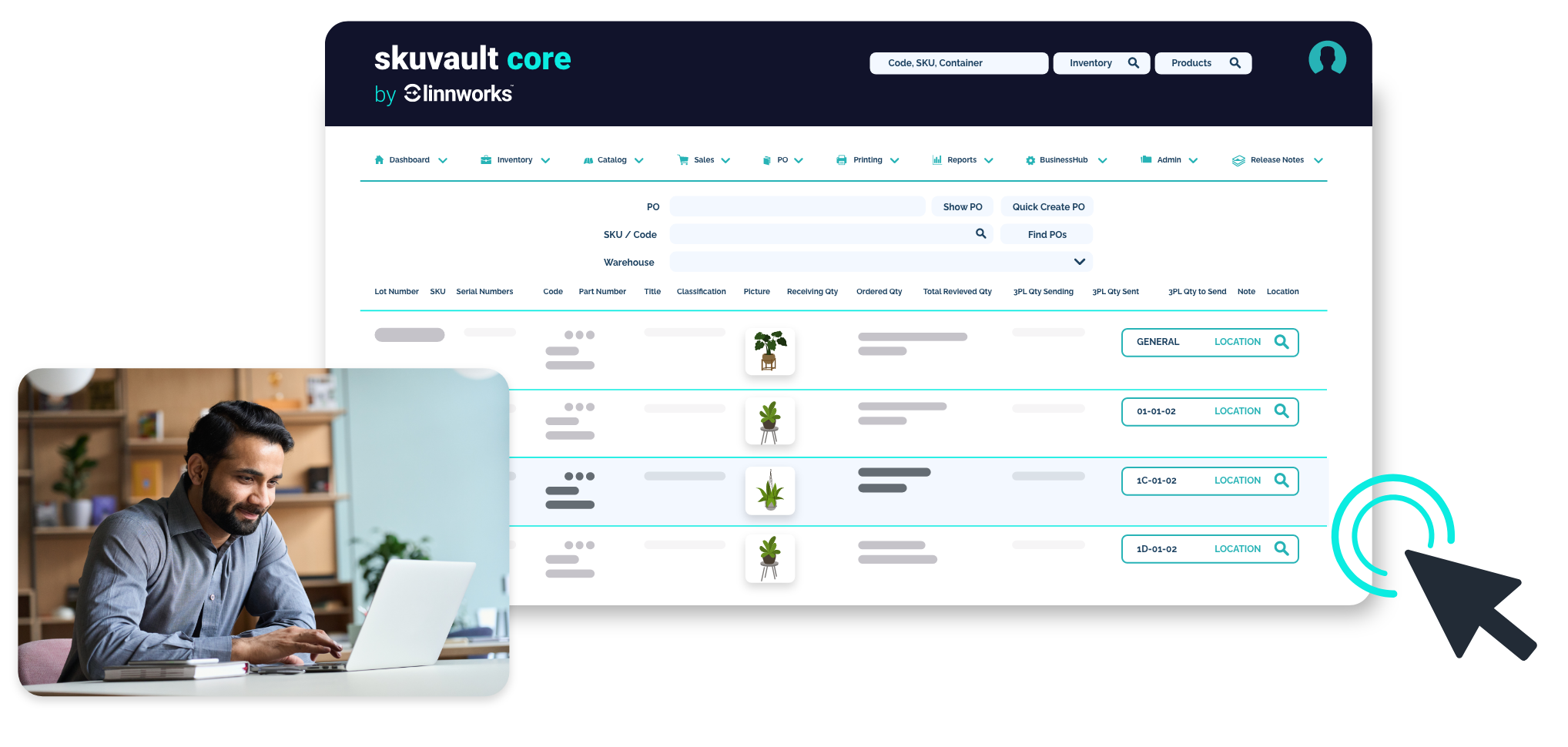

This is where manual processes fall short, and inventory forecasting saves the day. Having immediate, visualized access to past purchasing data is something only an IMS platform like SkuVault can provide.

Even better, SkuVault Core allows for drill-downs into historical data of particular channels, so you can stock intelligently for the holidays (or any other seasonal trend) on a channel-by-channel basis.

6. Implementing a scanning system

If there’s a process you can automate humans out of, odds are you should jump on that opportunity. Automation supports accurate inventory tracking and reduces inventory shrinkage.

Barcodes are cheap, and human error can be astronomically expensive.

It’s an inventory management best practice to scan items whenever you receive, move, ship, or alter them in any way. Without a scanning system, that opens you up for lots of human error, mistyped SKU numbers, and garbage inventory data.

This becomes especially pernicious as your ecommerce business grows beyond just a few SKUs in a small warehouse.

The ultimate guide to maximizing profit with SKU-level data

Linnworks and Conjura show how tracking profit and costs at the SKU level drives growth, boosts profitability, and supports data-driven decisions.

7. Set your par levels (minimum viable stock)

Par levels act as a safety net for ecommerce sellers by ensuring a minimum quantity of stock at all times. This helps to maintain optimal inventory levels and prevent stock-outs.

Assuming you’re not dealing with food or perishable items, all ecommerce business owners should have a minimum viable stock.

The process of setting par levels depends fundamentally on two variables: your products’ demand patterns and manufacturing timelines.

Some IMS platforms will automatically alert administrators when particular product SKUs fall below the par level threshold, taking into consideration a host of variables.

These include how long it takes to receive a new product, the demand curve for that particular SKU, and your current stock levels.

SkuVault Core not only intelligently recommends when new products should be ordered for optimal stock levels and revenue but assembles a purchase order automatically.

This handy feature of SkuVault Core, known as the Replenishment Report, takes into account all relevant supply, demand, and inventory variables, saving you the tedium of sorting through each product’s par level manually.

Here’s a simple example:

Let’s say you have a product that, on average, sells about one unit per day. You know that it takes 30 days to manufacture and fulfill that product in your warehouse. Therefore, your par level must be over 30 units to avoid stock-outs.

And this is a very simple example. Most purchasing trends aren’t this cut-and-dry and fluctuate greatly throughout the year. Therefore, your par levels must constantly be evolving to accommodate demand.

And all these considerations are just for one particular product! You’ll need to assess each product on a case-by-case basis if you want to stock intelligently.

This is just another reason why an IMS platform — especially one that provides historical data on purchasing patterns — is so crucial for automating the tedium that profitable inventory management requires.

8. Prioritize products with an ABC analysis

Once you’ve established a foundation of an inventory management philosophy, accurate demand projections, and data-backed par levels, it’s time to segment your product line.

Performing an ABC analysis helps you maximize your revenue by tailoring your fulfillment strategy to individual product categories and improving overall inventory management techniques.

For example, Category A might include products that are high in value but low in quantity. Category B; products that are moderate in value and moderate in quantity. And Category C; products that are low in value and high in quantity.

Bucketing your inventory this way allows organizations that sell diverse product lines to create bespoke restocking strategies for each product category.

9. Implement inventory management software

We’ve been mentioning this point sporadically throughout this post, but it’s best we just come out and say: every system in business reaches a point where manual processes just don’t cut it anymore.

You may have been able to get away with a static Excel spreadsheet or even paper-based inventory in the past. But if growth of any kind is on your radar, you need to adopt inventory management software.

And (speaking to busy ecommerce business owners here), do you really want to spend your time manually building Excel reports and digging through old files for historical data?

The ability to automate all that tedious (yet important) work is one of the many benefits an IMS brings to your organization.

But platforms like SkuVault Core don’t just stop managing inventory numbers and doing basic inventory counts; thanks to the power of integrations and APIs, you can actually turn your IMS into a makeshift enterprise resource planning (ERP) solution.

We’ll talk more about that in the integrations section of this post, or you can check out this article on the differences between ERP vs. an IMS.

10. Regularly audit your supply chain

Ecommerce operations that require a lot of kitting or assembly likely have multiple suppliers or manufacturers from which they order products or raw materials. Regular inventory audit practices can help identify supply chain disruptions early.

Common examples include handmade jewelry, proprietary formulas, or electronic components.

However, even if you only have one or two suppliers in your supply chain, this exercise is worth performing.

Set a recurring reminder every six months or so to plot out all the key parts of your supply chain and audit their contributions to your business. This includes things like:

- Measuring lead times against competitors

- Measuring cost against competitors

- Measuring any sort of negative trends (customer returns, defective products) that may necessitate a change

You may realize a supply problem in your ecommerce business isn’t due to any fault of your own but a faulty link in your supply chain.

11. Conduct cycle counts in your warehouse

All-hands-on-deck audits that require a complete shutdown of warehouse operations are obsolete, unsafe, and inefficient. Plus, nobody likes them.

Of course, we’re firm believers in frequent, meticulous inventory auditing. So what’s the solution? Cycle counting.

Cycle counting is a way to divide inventory counting responsibilities over the course of several days and employees. This supports accurate inventory records without halting warehouse inventory workflows.

You start by prioritizing the highest-value products (those in the A category if you’re already performing an ABC analysis) and have multiple employees (or just you if you’re a solopreneur) work a portion of their shift, counting those products.

Then, you move on to the B and C category products, which you count less frequently due to their lesser contributions to your bottom line. The frequency of your cycle counts depends on how conservative you want to be in shoring up inventory problems.

12. Integrate your technology stack into one “single source of truth”

As your ecommerce business grows, so does your monthly software bill, your list of logins and passwords, and how many browser tabs you have open at any given time.

Think about it, most successful ecommerce business owners have separate software platforms for:

- Inventory management

- Accounting

- Email marketing

- Invoicing

- Website

- Point-of-sale systems

And this doesn’t even take multiple sales channels into consideration! On top of managing all these platforms, you need to stay on top of sales from Amazon, eBay, Etsy, and any brick-and-mortar online portals.

It’s enough to make you want to crawl into the fetal position under your desk. Thankfully, many modern inventory management solutions like SkuVault facilitate integration with platforms across the spectrum of business functions and help establish a unified inventory management system.

Whether that’s Quickbooks for accounting, Shopify for point-of-sale, or Salesforce for your CRM, SkuVault Core integrates with them all.

That means you can have one single source of truth that not only shows you all your essential business data but communicates that data across all your mission-critical platforms.

Take a self guided tour of SkuVault Core

Find out how inventory management can help streamline your processes and help grow your business

13. Implement an intelligent picking strategy

We’ve said it many times on our blog, but time in a warehouse is measured in seconds, not minutes. Increasing your profitability often means picking products from your shelves faster and more accurately.

This is why we recommend implementing an intelligent picking strategy that’s a bit more thought out than just printing out a piece of paper and wandering the warehouse aimlessly.

There’s the classic wave picking strategy, which involves planning each day’s orders in advance and batching them by certain criteria. These batches are then released in “waves” that all employees work on simultaneously until the job is done.

However, we’ve developed an even better way forward: Hyper Picking.

Hyper Picking is a digital form of picking similar to wave picking. However, Hyper Picking utilizes an intelligent location system and filters from wave-picking sessions to create the most efficient pick route possible.

Managers can automate picking sessions by filtering the highest-priority orders. If you use physical bins, Hyper Picking even allows the option of picking based on the capacity of bins in a cart.

Filters are especially helpful during Hyper Picking because they dramatically decrease fulfillment time. Managers can assign filters to specific employees and immediately populate their pick lists instead of having to manually create them.

14. Create a quality control checkpoint in your shipping workflow

No inventory management technology or fancy processes trump the importance of good customer experiences. Happy customers equal more sales, full stop.

Quality control is the final safety checkpoint; the arbiter of positive customer experiences. Eliminating even a small percentage of errors can prevent customer order issues and improve customer satisfaction.

At the end of the day, you (and your warehouse employees) are human. Mistakes will happen, incorrect products will be picked and packed, and items will get damaged.

However, if you can eliminate even just 10% of those errors, it could be the difference between a loyal customer and a disgruntled detractor.

SkuVault Core comes with built-in quality assurance tools that help users take that extra step to avoid mis-picks and shipping defective products.

15. Physically organize your warehouse layout according to demand

After performing an ABC analysis, you may be aghast to discover that your most in-demand and high-value products are the farthest away from your processing area.

How much time could you save if you reorganized your warehouse layout to keep your top sellers within arms’ length of where product is processed and shipped?

Further, if you notice trends of customers bundling SKUs as add-ons (DSLR cameras and SD cards, for example), consider orienting your warehouse to keep those products in close proximity. This improves inventory movement and overall warehouse efficiency.

What is ecommerce inventory management?

Simply put, ecommerce inventory management is the discipline of measuring the amount, location, pricing, and mix of products available from your business.

However, this is just a baseline. Intelligent inventory management does a lot more, such as:

- Help coordinate the delicate balance of supply, demand, and communication with suppliers and end-users

- Give visibility into what products are overstocked, in stock, understocked, and out of stock

- Calculate per-pallet revenue potential

- Analyze and visualize purchasing trends, customer demand, and seasonal variables, allowing you to make intelligent business decisions to maximize revenue

The bottom line is that intelligent inventory management is an essential skill in today’s internet age just like content marketing, lead generation, or SEO.

Managing your inventory properly trickles into every part of your business. Neglecting this crucial area leaves a lot of money on the table and risks infecting other, seemingly unrelated, aspects of your organization.

Why should you care about ecommerce inventory management?

You should care about eCommerce inventory management because, frankly, it’s a non-negotiable for business success. It ensures positive customer relations by avoiding common frustrations such as out-of-stock items, inaccurate shipping expectations, or wrong products shipped.

A good buying experience will lead to repeat business and customer advocacy, the flywheel of success for any ecommerce operation.

Furthermore, efficient inventory management (ideally aided by inventory management tools) provides precise knowledge of what you have in stock, an absolute necessity for growing businesses.

Without it, managing multiple warehouses, employees, and orders can become chaotic.

Utilizing a robust ecommerce inventory management system like SkuVault Core can streamline the process, helping to handle growth and maintain organized inventory information.

Smart inventory management boosts revenue potential. Despite often being overlooked in favor of other “shinier” ways to generate revenue, it is one of the most powerful levers ecommerce businesses have to cut costs, save time, and reduce errors.

Why implement inventory management software?

We’ve barely scratched the surface of inventory management for ecommerce, but it’s likely that many reading this are already feeling overwhelmed.

The bottom line is that trying to manage anything more than a casual, side hustle ecommerce business without a dedicated IMS platform is a fool’s errand.

Let’s dive into some of the distinct benefits that a tool like SkuVault Core can provide your business.

Inventory management software enables rapid growth

When you have a platform like SkuVault Core at the center of your inventory management strategy, the headache of scaling your product storage — and, ultimately, your business — is removed.

While warehouses may grow, product lines may expand, and more employees may be necessary, your inventory workflow stays the same.

SkuVault Core still aggregates all your channels, warehouse information, and purchasing analytics in one central place. No matter how much your organization scales, the fundamentals of replenishment and inventory management stay the same — and SkuVault Core keeps it simple.

Real-time visibility into all your channels

If I asked you about the sales performance of your flagship product on Amazon vs. brick-and-mortar stores, how quickly could you produce those figures? What about if you wanted to know your per-pallet revenue potential for website sales?

This level of granularity is not only possible but takes seconds to access with a tool like SkuVault Core. This also helps prevent dead stock by assigning inventory to specific channels as opposed to a haphazard restocking en masse.

Decreased lead time through intelligent picklists and pick routes

All you need to do is watch a YouTube video on Amazon’s warehouse to understand that inventory management is measured in seconds, not minutes.

To say time is of the essence would be a gross understatement. That’s why SkuVault includes intelligent pick lists and pick routes.

When a customer places an order, SkuVault delivers detailed instructions to the picker. In addition to quantity information and product location, picklists show the most efficient route to gathering the products based on where they are in your warehouse.

These picklists are available in both digital and printable form, helping warehouse employees process orders as quickly as possible.

This decreases the lead time for processing and shipping and makes for a more efficient warehouse and much happier customers.

Data tracking and insights

If the sound of data analysis sounds soul-crushing to you, you’re not alone. But data that directly pertains to money going into your pocket? That’s exciting.

IMS platforms like SkuVault offer a wide range of at-a-glance analytics available on all your devices.

This means demand forecasting, inventory vs. demand curves, and replenishment schedules are only a few clicks away.

Not only do these reports in SkuVault save a ton of headaches and grunt work, but they give you a clear path forward on how to safeguard against the future.

The analytics available will also help you know when to scale back your fulfillment and how to bypass costly roadblocks in every stage of the ecommerce lifecycle.

With SkuVault, you’ll learn to love data like never before.

Intelligent replenishment insights

SkuVault’s Replenishment Report feature expands on the principle of minimum viable stock, creating an automated replenishment schedule based on your unique business needs.

The report takes into consideration your desired par level, along with your customer’s purchasing habits and demand forecasts. The app can generate custom purchase orders for particular products and quantities, too.

Making the most out of each pallet has never been easier with SkuVault.

Next steps

ecommerce inventory management is anything but simple. Thankfully, we’ve built SkuVault Core to be the best inventory management software; one that does all the heavy lifting for you.

That way, you can get back to high-level tasks like strategy, growth, and maximizing your revenue.

For more information on how SkuVault Core can help, contact our team today for a demo.

FAQs

Ecommerce inventory management is the process of managing inventory across all your sales channels so you always know how much inventory you have, where it’s located, and when to reorder. It includes everything from inventory tracking and inventory accuracy to forecasting customer demand and maintaining optimal inventory levels. Effective ecommerce inventory management improves operational efficiency, reduces errors, and ensures positive customer satisfaction.

Without strong inventory management, ecommerce operations quickly run into problems like stockouts, excess inventory, delayed order fulfillment, and supply chain bottlenecks. Accurate inventory data helps you make better decisions about purchasing, inventory cost, production, and fulfillment. Most importantly, it ensures customers get the right inventory item at the right time.

Some widely used inventory management best practices include doing regular cycle counts, using a perpetual inventory system, implementing an ABC analysis, conducting regular inventory audits, improving warehouse layout, and integrating systems into one inventory management system. These best practices help maintain accuracy, minimize inventory shrinkage, and streamline your entire inventory management process.

Modern inventory management software centralizes your inventory record, automates tedious tasks, improves inventory turnover, and creates real-time visibility across multiple warehouses or channels. An IMS helps reduce picking errors, supports smarter purchasing through inventory forecasting, and offers insights that directly improve operational efficiency and warehouse management.

Inventory control focuses on what’s happening inside the warehouse — maintaining accurate stock counts, preventing inventory shrinkage, and ensuring products are stored properly. Inventory management, on the other hand, is broader. It includes forecasting demand, optimizing inventory levels, managing suppliers, avoiding supply chain disruptions, and improving your overall supply chain management strategy.

Excess inventory often stems from inaccurate forecasts, unclear reorder points, slow-moving SKUs, or poor inventory tracking. Preventing overstock starts with better inventory forecasting, establishing clear par levels, conducting a regular inventory audit, and using inventory management techniques like ABC analysis to prioritize products based on value and velocity.

Improving inventory accuracy is all about consistency. Scan products during every inventory movement, maintain a well-organized warehouse layout, use barcodes, and conduct regular physical inventory counts or cycle counts. When paired with warehouse inventory management tools, these practices drastically reduce miscounts and improve the reliability of your inventory record.

Efficient order fulfillment comes down to optimizing pick paths, reducing travel time in the warehouse, and using an intelligent order management system. Techniques like wave picking, zone picking, or digital routing increase speed and accuracy while improving overall warehouse inventory flow.

Strong inventory turnover — and a healthy inventory turnover ratio — means products are selling consistently rather than sitting idle. Faster movement reduces storage costs, protects you from spoilage or obsolescence, and boosts cash flow. Low turnover is often a sign of poor forecasting, weak inventory management processes, or misalignment with customer demand.

Managing inventory across multiple warehouses requires a unified inventory management system that syncs stock levels, routes orders intelligently, and keeps your inventory data consistent everywhere. Centralized software ensures each location has the right inventory items and prevents costly fulfillment delays or stock imbalances.