Why inventory accuracy matters for order fulfillment and operational efficiency

Most retailers believe their inventory data is reliable. The numbers in their system reflect what is on their shelves, or so they think. In reality, the average U.S. retailer operates with an inventory accuracy rate of just 65%. That means for every ten items a system claims to have in stock, more than three are statistically likely to be missing, misplaced, or damaged.

This is not a rounding error. It is structural dysfunction built into the operation’s foundation, and it compounds with every order processed against bad data.

The gap between recorded inventory and physical inventory drains revenue, threatens marketplace standing, and caps how far an operation can scale. In 2026, where platforms like Amazon penalize cancellations instantly and customers have near-infinite alternatives a click away, operating at 65% accuracy is a problem that manages you, not one you manage.

This guide covers what inventory accuracy actually means, why it degrades, how it affects order fulfillment and warehouse efficiency, and what separates the operations that consistently hit 99% from those stuck at the industry average.

Inventory and warehouse management savings calculator

Uncover the cost of your mis-ships, out of stocks and lack of labor efficiency with our inventory management savings calculator.

What is inventory accuracy (and how is it measured)?

Inventory accuracy is the degree of alignment between your recorded inventory levels (what your inventory management system says you have) and your actual inventory: what is physically in your warehouse, on your shelves, or in your bins. When those two numbers match, your operation runs as designed. When they diverge, every downstream process that depends on inventory data starts making decisions based on fiction.

The measurement is straightforward:

Inventory Accuracy Rate (%) = (Items Counted Correctly ÷ Total Items Counted) × 100

If you count 1,000 SKUs in a physical inventory count and 920 match your system records exactly, your inventory accuracy rate is 92%. That sounds reasonable until you do the arithmetic on what that 8% costs you. One in ten items wrong, across a warehouse processing thousands of orders daily, generates a constant, expensive stream of mis-picks, cancelled orders, and customer complaints. And 92% is well above the industry average.

A decade ago, 90% accuracy was broadly considered good enough for most operations. Multi-channel commerce has changed that calculus in a specific, measurable way: when a single SKU is listed on Amazon, Shopify, and eBay simultaneously, one miscounted item does not create one problem. It creates three, one per channel, each with its own penalty structure. The target for any multi-channel operation that wants to grow without cascading failures is 99% or higher.

A few related definitions worth keeping distinct: stock accuracy refers to whether the right quantity of the right item is in the right location, a more granular standard than simple count accuracy. An accurate inventory count is the process of verifying physical inventory against recorded inventory. Regular inventory audits are the scheduled reviews that maintain alignment over time.

Together, they form the foundation that everything downstream depends on, and the practices required to achieve each are not the same.

The real cost of inaccurate inventory

Inaccurate inventory data is routinely described as an operational inconvenience. A more accurate description is a financial leak with multiple openings: some obvious, some slow, and some that only become visible once they have already done significant damage.

The most visible penalty

A stockout occurs when a customer tries to purchase an item that is either physically unavailable or that the system mistakenly shows as available when it is not. The immediate cost is a lost sale, but that is only the entry point.

Correcting a stockout through emergency replenishment typically costs three to five times more than standard procurement, destroying the margin on the eventually sold goods. Meanwhile, the customer who encountered the stockout is not simply waiting patiently. Research shows that 75% of customers are likely to switch to a competitor after experiencing just two such incidents, meaning each stockout carries the risk of losing not one transaction but the entire future value of that customer relationship.

On marketplace channels like Amazon, there is an additional cost that rarely appears in post-mortem analyses: ranking loss. When a product goes out of stock, its sales velocity drops to zero. The algorithm responds by demoting it in search results. Recovering that organic visibility after a stockout typically requires significant PPC advertising spend, a cost that arrives weeks after the original event and is almost never attributed to the inventory failure that caused it. The financial damage from a single stockout is always larger than it looks at the time.

The capital trap

The predictable response to unreliable inventory data is over-ordering. Lacking confidence in what the system shows, buyers pad their safety stock buffers. It is a rational decision given the information they have, but one that creates its own compounding costs. Carrying costs for excess inventory typically run 20 to 30% of inventory value annually, meaning a business holding $500,000 in excess stock is effectively spending $100,000 to $150,000 per year for the privilege of not knowing what they actually have.

Amazon’s aged inventory surcharges add a further layer of penalty, charging $0.35 per unit or $7.90 per cubic foot for items held longer than 15 months. The longer inaccurate stock sits undetected, the more likely it becomes obsolete, damaged, or out of season, forcing liquidation at discounts that can fall below cost.

For a business carrying $1 million in inventory, reducing unnecessary safety stock by 20% releases $200,000 in working capital. That could generate growth that has not happened yet because it is warehoused in items the system cannot accurately account for.

Linnworks demo: how to master inventory management

Centralize stock and automate updates across all your sales channels effortlessly.

How inventory accuracy directly impacts order fulfillment

Inventory accuracy is the mathematical ceiling of your Perfect Order Rate, the percentage of orders that arrive on time, complete, undamaged, and with correct documentation. When inventory data is accurate, the fulfillment chain functions as designed: pickers follow optimized routes to confirmed locations, orders ship on time, and customers receive exactly what they ordered. When inventory data is wrong, every step in that chain becomes a potential failure point.

The drag is measurable and specific. In a warehouse where 5% of inventory locations contain errors, pickers encounter exceptions on 50 out of every 1,000 orders. Each exception breaks the pick path and requires supervisor intervention, creating 50 disruptions per day that compound into a constant drag on throughput before a single customer complaint arrives.

Sending the wrong item is worse than sending nothing at all. It forces the customer through a high-friction returns process, generates a negative review that damages future conversion, and costs the business twice: once to fulfill the wrong item, once to correct it. An email telling a customer that the item they ordered is actually out of stock is a trust failure, and as noted earlier, 75% of customers report they will switch to a competitor after just two such experiences.

Marketplace compliance makes this even less forgiving. Amazon requires cancellation rates below 2.5% and penalizes poor inventory management through its Inventory Performance Index (IPI), with consequences ranging from storage restrictions to account suspension. eBay treats every wrong-item shipment as a formal defect, tracked against the seller’s standing. TikTok Shop’s fulfillment windows are aggressive, and meeting them consistently is not possible when warehouse organization is compromised by inaccurate inventory data.

The marketplaces are not being unreasonable. They are reflecting what customers already expect. The businesses that treat this as an external constraint to manage rather than a standard to internalize will keep losing ground to those who have.

Root causes of inventory inaccuracy in multi-channel operations

Inventory discrepancies do not usually have a single cause. They accumulate from multiple failure points, technical, procedural, and structural, often running simultaneously. Diagnosing which failure points are dominant in your specific operation is the prerequisite to fixing any of them.

Synchronization lag and race conditions

The most common technical cause of inaccuracy in multi-channel retail is time lag. Many basic integration tools rely on polling, checking for updates at set intervals, rather than real-time push notifications.

That gap is precisely where overselling happens. Consider a retailer with five units of a popular item: three sell on Amazon at 10:00 AM, three more sell on eBay at 10:05 AM, and the inventory sync runs at 10:30 AM. The system has just sold six units against a stock of five, and no one knows until cancellations start arriving.

During peak periods like Black Friday, when sales velocity spikes and transactions stack within seconds of each other, this window of vulnerability does not just persist. It widens proportionally. Because the problem is architectural rather than configurational, tightening polling intervals only narrows the exposure window; eliminating it requires push-based sync.

Human error in manual workflows

Despite widespread adoption of digital tools, many mid-market operations still rely on manual data entry at key touchpoints, and manual entry is reliably error-prone in ways that compound over time.

A receiving clerk who keys in 1,000 units instead of 100 corrupts the system from the first record. Without strict purchase order matching, that error persists until a physical inventory count surfaces it, potentially months later, after it has generated dozens of downstream failures in the form of oversells, stockouts, and emergency replenishments.

In warehouses with high SKU density, visual picking creates a different class of error. A picker grabs a Medium Blue shirt instead of a Large Blue shirt — they look nearly identical in a busy warehouse. Without barcode validation at the point of pick, both SKU counts are now wrong simultaneously. Neither error surfaces until a customer receives the wrong item and files a complaint. By that point, the problem has left the building.

Disconnected systems and data siloes

A retailer using Shopify for their website, a legacy WMS for their warehouse, and a spreadsheet for wholesale orders is maintaining three separate versions of inventory reality. When those versions diverge, and they will, discrepancies accumulate silently.

Research suggests that fragmented tech stacks reduce inventory visibility by up to 40%. Returns illustrate this particularly clearly: an item processed in the warehouse that does not trigger an update in the sales channel leaves sellable stock invisible to every buyer. The warehouse knows the item is available. The sales channel does not. No one sells it. No one investigates. The revenue disappears into the gap between systems.

Bundle and kit complexity

Bundles create a geometric accuracy problem that basic platforms are not designed to handle. When a component of a kit sells individually, the system needs to immediately reduce the available quantity of every bundle that includes that component, across every channel. Most entry-level platforms do not do this natively, treating the bundle as a static item rather than a calculated quantity derived from component stock. The result is that component-level sales create silent kit availability errors that accumulate invisibly and surface as oversells.

Bundle complexity at least announces its failure mode through oversells. Shrinkage is quieter: physical losses that never get formally processed leave the system confidently wrong about items that no longer exist.

The shrinkage factor

Shrinkage — damage, spoilage, theft — creates discrepancies when physical losses are not formally processed in the system. An item thrown away without being adjusted out remains on the books indefinitely.

A return placed in a quarantine bin that is never formally received back into stock sits in operational limbo: technically available to sell, physically unreachable. The system will try to fulfill orders against it. Every time it does, a picker will fail to find it. The exception will require resolution. And the root cause will go unaddressed until someone counts that bin.

Why fixing these problems can be harder than it sounds

Most advice in this space makes correction sound straightforward: implement cycle counting, add barcode scanning, integrate your systems. The steps are correct. What the descriptions tend to understate is how much each practice depends on adjacent conditions being true at the same time.

Cycle counting is a good example. The logic is sound: count a rotating subset of inventory daily rather than shutting down for an annual physical count. But in a high-SKU-density operation with limited floor staff, daily counting competes directly with pick-and-pack throughput. Counting slows the warehouse. Peak periods make consistent counting nearly impossible. Without purpose-built mobile workflows that allow staff to count in-aisle between picks rather than as a separate scheduled activity, cycle counting often collapses back into the annual count it was designed to replace.

Barcode scan validation at receiving is similarly harder to sustain than to implement. It requires that every inbound shipment arrives with scannable labels, that the receiving team is trained and disciplined about the workflow, and that the WMS is configured to reject non-matching scans rather than quietly accept them. Each of those conditions requires ongoing management.

This is worth naming plainly: the challenge is not knowing what to do. The challenge is building an environment where the right thing is also the path of least resistance. That is a system design problem, and it is the reason platform selection matters as much as process design. Layering good practices onto inadequate tools produces temporary results.

Best practices for maintaining inventory accuracy

The practices that address the root causes above are well established. What determines whether they stick is whether they are built into the workflow or bolted on top of it.

Replace annual audits with cycle counting

Closing the warehouse for a week once a year is expensive, disruptive, and leaves errors running undetected for eleven months at a stretch. Cycle counting, auditing a rotating subset of SKUs continuously, catches discrepancies while they are still fresh enough to investigate and trace. A standard ABC approach counts high-velocity A items monthly, B items quarterly, and C items semi-annually, completing full inventory verification without ever stopping operations.

The practice only sustains itself when counting is integrated into the normal flow of warehouse work through mobile in-aisle workflows. Operations that schedule counting as a dedicated activity find that it consistently loses to pick-and-pack throughput, reverting to the annual count within one peak season.

Implement barcode scan validation

Visual verification fails at scale, and it fails in ways that are invisible until a customer receives the wrong item. Every inventory movement (receiving, put-away, picking, packing) should require a scan confirmation. Scan-to-pick is the single most effective method for eliminating shipping errors: when the wrong barcode is scanned, the system rejects it immediately, before the error leaves the warehouse floor.

Where this practice erodes after implementation, the cause is almost always exception handling. When a scannable label is missing or damaged and no clear protocol exists, staff default to visual confirmation as a workaround, and that workaround spreads. The discipline of scan validation is only as strong as the system’s willingness to reject non-scanned exceptions and its consistent enforcement when items arrive without proper labels.

Linnworks demo: how to master inventory management

Centralize stock and automate updates across all your sales channels effortlessly.

Enforce purchase order matching

Most inventory inaccuracy originates at the receiving dock, which means most of it could be caught before it ever enters the system. Every inbound shipment should be matched against a PO before quantities are entered, and any discrepancy should trigger investigation rather than passive acceptance.

A receiving error that enters the system cleanly is indistinguishable from accurate data. It will not surface until it causes a customer-facing failure, by which point it has already generated overstock decisions, mis-picks, or cancellations downstream. Time pressure is the specific failure mode here: when inbound volume spikes and the receiving team is behind, PO matching gets skipped to clear the dock. The practice has to be enforced at the system level, requiring PO confirmation before quantities post, not left to staff compliance under pressure.

A single source of truth

Fragmented tech stacks generate fragmented inventory records. The structural fix is a central inventory management system that maintains a single master record and pushes real-time updates to every connected channel the moment any inventory movement occurs, eliminating the synchronization gaps that create race conditions and the data isolation that generates phantom inventory.

One failure mode worth acknowledging that the conventional advice on centralization tends to skip: integration drift. Businesses implement a central system and achieve synchronization at launch, then add a new channel, a new warehouse location, or a new point-of-sale tool that connects imperfectly or not at all. Each addition creates a new edge where data falls out of sync. Maintaining a true single source of truth is an ongoing governance commitment, not a one-time architecture decision.

Build continuous improvement into regular audits

Inventory accuracy degrades over time without active maintenance. The most effective operations use automated discrepancy flags (negative stock counts, sudden quantity changes, bin locations that have not moved in anomalous ways) to surface problems proactively, before they generate customer-facing failures.

Diffuse ownership is what kills this in practice. When discrepancy alerts go to a general inbox, or to whoever happens to notice them, follow-through is inconsistent. Accuracy improvement requires a named person or team responsible for investigating flags, closing the loop on discrepancies, and tracking whether error rates are trending in the right direction. Without that accountability structure, the alerts become noise.

The operational efficiency case for high inventory accuracy

Beyond individual orders, inventory accuracy shapes how warehouse space is used, how labor is deployed day to day, and whether the operation can absorb volume growth without proportional cost growth, making it as much a cost structure question as a fulfillment metric.

Warehouse space and utilization

Inaccurate inventory creates a specific kind of waste: the warehouse that appears full in the system while being physically underutilized. When a WMS believes a bin is occupied when it is empty, that space goes unallocated. New stock arrives with nowhere to go, and staff leave it in aisles or staging areas, creating congestion and safety hazards. The inverse problem is equally common: a system that shows empty bins when they are actually full sends receiving teams hunting for available locations that do not exist.

Both scenarios waste labor and space. Warehousing costs have risen more than 4% year over year, meaning every misallocated bin represents real lease cost, not a theoretical inefficiency. Accurate data enables dynamic slotting, with high-velocity items positioned at accessible locations and slow-movers condensed and clearly identified. That kind of continuous optimization is not possible without reliable counts.

Inventory management savings calculator

Uncover the cost of your mis-ships, out of stocks and lack of labor efficiency with our inventory management savings calculator.

Labor productivity and workforce retention

When inventory data is accurate, warehouse managers can staff predictably: they know the order volume, they know where everything is, and they can set their labor accordingly. When data is unreliable, they overstaff as a hedge against exception-handling friction, paying for labor hours that exist entirely to compensate for a data problem.

There is a morale dimension here that is easy to dismiss but genuinely costly. Anyone who has managed a warehouse floor knows that sending a picker to an empty bin once is an inconvenience; sending them to empty bins repeatedly erodes both morale and retention. Turnover is already a serious problem in an environment where labor shortages currently affect 78% of warehouses. Keeping experienced staff is a competitive advantage, and accurate data is part of what makes it possible.

Sustainability and ESG

Fulfillment errors driven by inaccurate inventory generate a category of waste that is increasingly relevant to enterprise procurement: unnecessary reverse logistics. A wrong-item shipment creates an additional transport leg that would not exist if the pick had been correct, doubling the packaging consumed and adding a carbon-generating route to an order that should have been closed on first delivery. For retailers with wholesale or B2B revenue channels, this is worth monitoring. Logistics-related emissions are a standard line item in sustainability audits, and the connection between mis-pick rates and preventable transport waste is increasingly visible in procurement review cycles.

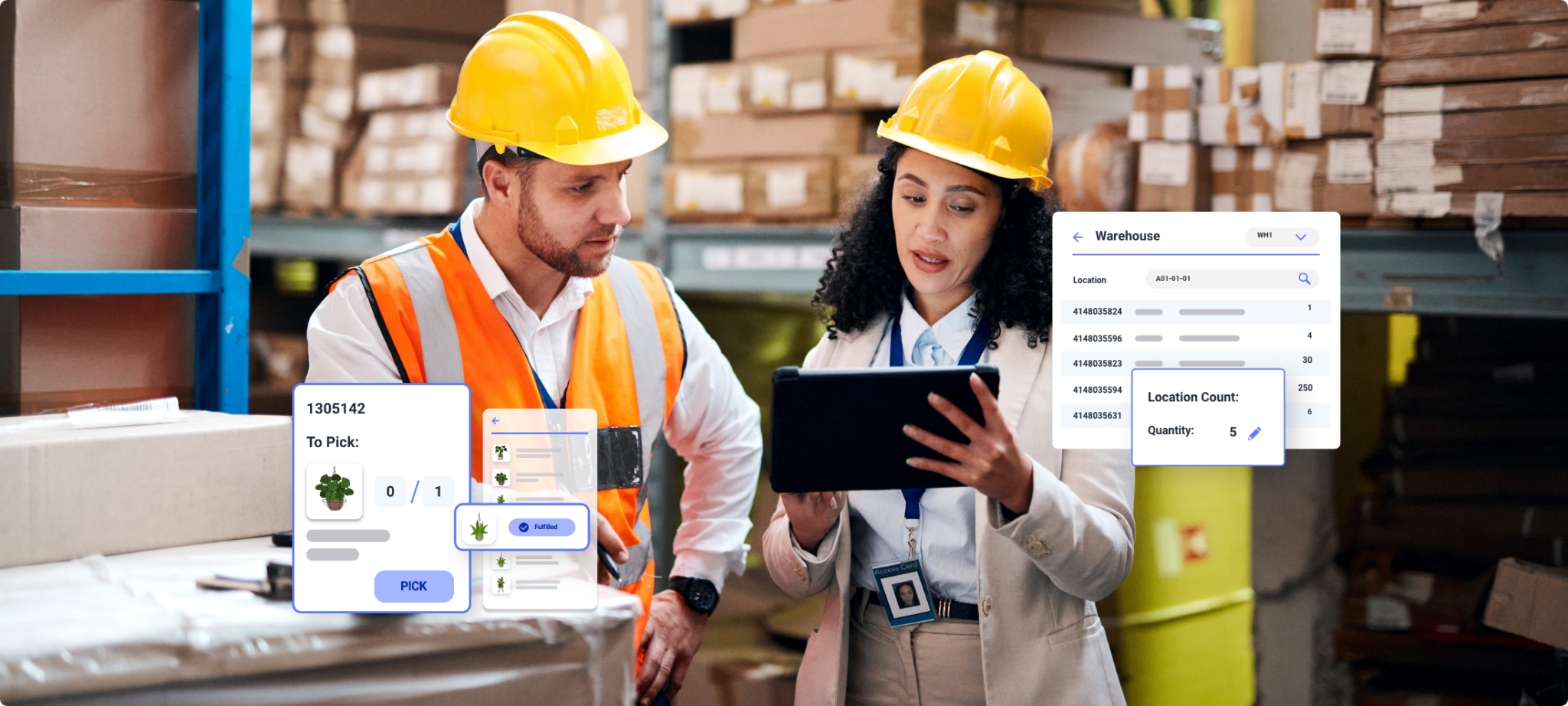

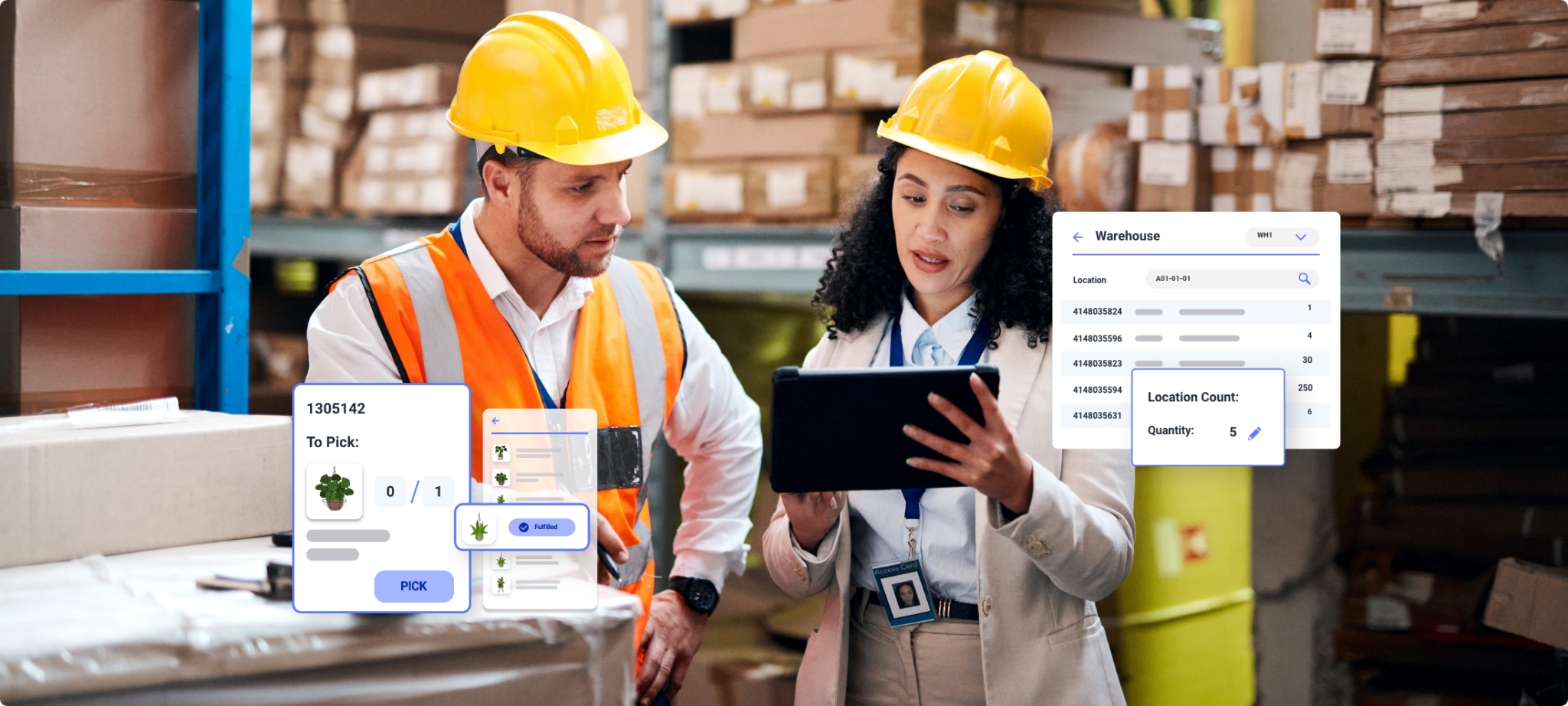

How Linnworks addresses inventory accuracy in practice

Most inventory management platforms make similar claims about centralization and real-time sync. What distinguishes Linnworks for mid-market retailers (those operating across multiple channels with meaningful SKU counts and fulfillment complexity) is that its architecture addresses the specific failure points described above, rather than offering generic inventory tracking on top of a commerce platform.

That said, the platform requires setup investment and discipline to deliver its benefits. The accuracy gains come from using the system’s enforcement features (barcode validation, PO matching, composite item logic) consistently. That caveat applies to any serious inventory management system, and Linnworks is no exception.

Real-time multichannel sync

The race condition problem described in the root causes section, where the lag between a sale and an inventory update creates a window of overselling, is an architectural issue, not a configuration issue. Linnworks resolves it at the architecture level: when an item sells on any of its 100+ connected channels, inventory decrements across all others in near real time via push updates rather than polling intervals.

The Sol Retail story is the clearest illustration of what this enables in practice. Sol Retail could not add channels without risking chaos, not because they lacked products or customers, but because their inventory management could not keep pace with simultaneous sales across platforms. After implementing Linnworks, they scaled revenue from £10 million to £25 million. The infrastructure that had been preventing channel expansion became the infrastructure that enabled it.

Scan-based validation throughout the warehouse

Barcode scanning at pick is the single most effective control for eliminating shipping errors, but its value depends entirely on whether the system enforces it rather than merely supports it. Linnworks’ system-directed picking requires a scan confirmation before a pick is accepted; if the wrong item is scanned, the system rejects it before the error moves downstream.

Composite items for kit and bundle management

The bundle accuracy problem, where components and kits get out of sync, is one of the most common causes of overselling in complex product categories, and one that many platforms handle poorly or not at all. Linnworks tracks each bundle component individually, calculates real-time kit availability from the component pool, and updates every channel the moment a component moves. When a component sells individually, the bundle availability adjusts automatically.

Linnworks Rules Engine for fulfillment automation

Manual decision-making at the point of fulfillment introduces errors that are disproportionately expensive to correct, not because individual mistakes are large, but because they happen at the moment of highest operational velocity, when there is least capacity to catch them. The Linnworks Rules Engine removes those decisions from human judgment entirely: a retailer shipping across the UK, EU, and US, for example, can configure rules that automatically route each order to the correct carrier based on destination, weight, and declared value, enforce channel-specific SLA windows without staff intervention, and ring-fence dedicated stock for B2B clients so that a spike in DTC volume cannot inadvertently deplete a wholesale commitment. The logic runs at order creation, before any pick is initiated, which means fulfillment errors that would otherwise require $50-per-incident corrections are prevented rather than caught.

The Rules Engine is powerful, but it depends on knowing which rules to build in the first place. That is where Spotlight AI comes in. Spotlight AI continuously analyzes operational workflows across the order lifecycle to identify where manual actions still exist, diagnose inefficiencies, and prescribe the specific automation rules that would have the greatest impact.

Rather than requiring operations teams to periodically audit their own processes (a task that rarely survives contact with peak season), Spotlight AI surfaces blind spots automatically: orders still being manually tagged, fulfillment centers being assigned by hand, shipping services selected one at a time when a rule could handle them in bulk.

In early testing, customers who implemented automation rules based on Spotlight AI’s recommendations saved an average of more than 30 hours of manual work per month. For operations teams already running the Rules Engine, Spotlight AI functions as a continuous optimization layer, closing the gap between what is automated and what should be.

Multi-location and international complexity

Spreetail needed a European distribution center operational, with full inventory transparency, in three weeks. Linnworks delivered. That speed matters because in international expansion, the cost of operating without synchronized inventory visibility compounds daily: orders that cannot be confidently allocated to the right fulfillment location either stall or generate the kind of cross-border shipping errors that are expensive to correct and damaging to marketplace standing in new markets. Linnworks’ multi-location architecture handles this through Extended Properties, which allow a single internal SKU to map to different external listings and regional requirements without manual reconciliation. Within a year of that implementation, Spreetail had achieved 6x growth in the European market.

For businesses expanding internationally, the alternative to a system built for this complexity is usually a patchwork of regional tools that do not communicate, which is precisely how disconnected data siloes form at scale, not from negligence but from growth outpacing architecture. Speed of deployment matters because complexity accumulates faster than most businesses plan for.

Final thoughts

The opening statistic in this piece, that the average U.S. retailer operates at 65% inventory accuracy, is worth sitting with, because it implies something that is easy to overlook: the majority of retailers are running operations where more than a third of their inventory data is simply wrong, and that structural dysfunction does not self-correct.

If your operation is in that majority, the path forward is not complicated, but it does require honest assessment. Start by measuring your actual inventory accuracy rate: run a physical count against your system records for a representative sample of SKUs and calculate the gap. That number will tell you more about your operational risk than most reports in your dashboard.

From there, the priorities sequence naturally. Fix the synchronization architecture first if you are multi-channel. Implement scan validation at receiving and picking second. Then address the systemic issues (bundling logic, return processing gaps, disconnected systems) in order of their contribution to your specific discrepancy rate. Each of those steps depends on having an inventory management system that enforces accuracy at the touchpoint rather than records what went wrong after the fact.

The retailers who are still operating at scale in three years will not be the ones who treated 65% as an industry benchmark. They will be the ones who recognize it as a description of their current ceiling and measure their way out of it.

Get a Linnworks demo – automate inventory and orders faster

Book a Linnworks demo and see how it simplifies inventory, orders, and fulfillment. Get started today and optimize your eCommerce operations.

FAQ

Inventory accuracy is the degree of alignment between your recorded inventory levels (what your inventory management system shows) and your actual inventory: what is physically present in your warehouse. It is measured using the inventory accuracy formula: Items Counted Correctly ÷ Total Items Counted × 100. Inventory accuracy matters for order fulfillment because every downstream process (picking, packing, shipping, and channel availability) depends on inventory data being correct. When recorded inventory and physical inventory diverge, the result is mis-picks, cancelled orders, oversells, and marketplace penalties. The average U.S. retailer operates at 65% inventory accuracy, meaning more than one in three inventory records is wrong, a level of inventory inaccuracy that actively limits operational efficiency and growth.

Inventory inaccuracies in multi-channel retail typically stem from several simultaneous failure points. Synchronization lag between sales channels creates race conditions where the same stock is sold twice before inventory levels update. Manual data entry at receiving introduces errors into inventory records from the first transaction. Disconnected systems (separate platforms for ecommerce, warehousing, and wholesale) produce fragmented inventory data with no single source of truth. Bundle and kit complexity causes component-level sales to silently reduce kit availability without updating every channel. And shrinkage from damage, theft, or spoilage that is never formally processed in the inventory management system leaves the recorded inventory confidently wrong about stock that no longer exists. Poor inventory accuracy is rarely the result of a single cause; it accumulates across all of these at once.

The inventory accuracy formula is straightforward: divide the number of items counted correctly by the total items counted in a physical inventory count, then multiply by 100 to get your inventory accuracy rate. An accurate inventory count for a warehouse with 1,000 SKUs that finds 920 matching system records yields a 92% accuracy rate, well above the industry average but still generating errors on roughly 1 in 10 items. For any multi-channel operation listing products on platforms like Amazon, Shopify, and eBay simultaneously, 92% is insufficient. A single inventory discrepancy creates one problem per active channel, each with its own penalty structure. The target for operations that want to scale without cascading fulfillment failures is 99% or higher. Maintaining inventory accuracy at that level requires cycle counting, barcode scan validation at every inventory movement, and an inventory management system that enforces accuracy at the point of transaction rather than recording errors after the fact.

Inaccurate inventory data creates compounding inefficiencies throughout warehouse operations. When inventory records don’t reflect physical inventory, warehouse managers overstaff as a hedge against exception-handling, paying for labor hours that exist solely to compensate for a data problem. Pickers sent to incorrect bin locations waste time and disrupt pick-path optimization. Inaccurate inventory levels also produce a warehouse that appears full in the system while being physically underutilized, leaving space unallocated and forcing new stock into aisles and staging areas. Excess inventory from over-ordering, itself a predictable response to unreliable inventory data, carries costs of 20 to 30% of inventory value annually. Accurate inventory records eliminate the friction that makes every operational process harder: labor can be scheduled predictably, space can be dynamically slotted, and fulfillment SLAs can be met consistently. High inventory accuracy is not just a fulfillment metric; it is a cost-structure advantage.

Maintaining inventory accuracy requires building the right practices into the workflow rather than adding them on top of it. The most effective approach replaces annual inventory audits with continuous cycle counting, auditing a rotating subset of SKUs daily so that discrepancies are caught while they are still traceable, rather than running undetected for months. Barcode scan validation at every inventory movement (receiving, put-away, picking, and packing) eliminates the visual verification errors that are invisible until a customer receives the wrong item. Enforcing purchase order matching at the receiving dock catches most inventory discrepancies before they enter the system at all. Centralizing on a single inventory management system that pushes real-time updates across every channel eliminates the synchronization gaps that create oversells. And regular inventory audits with clear ownership (a named person or team responsible for investigating discrepancy flags and tracking accuracy rate trends) ensure that continuous improvement doesn’t collapse into noise. Each of these practices depends on the others being in place; accurate inventory management is a system, not a checklist.