How to improve inventory accuracy and keep inventory levels under control

Inventory accuracy is the gap between what your system says you have and what’s actually on the shelf. That gap determines the reliability of every replenishment decision, forecast, and fulfillment promise you make.

Poor accuracy creates stockouts that disappoint customers, overstock that ties up cash, missed SLAs, and compounding costs. Higher accuracy reduces customer service volume because fewer shipments contain wrong items, enables precise reorder point calculations, and allows tighter safety stock targets without increasing stockout risk.

The difference between 85% accuracy and 98% accuracy is the difference between reacting to problems and preventing them.

This guide covers the tactics that actually work: cycle counts and audits that tighten accuracy, reorder points and ABC analysis that maintain optimal inventory levels, and the specific software features worth paying for when you’re ready to scale.

Inventory management savings calculator

Uncover the cost of your mis-ships, out of stocks and lack of labor efficiency with our inventory management savings calculator.

What causes inaccuracy in the first place

Most inventory problems start at receiving. Miscounts at the dock, pallets placed in incorrect locations, or similar SKUs confused because labeling systems haven’t kept pace with SKU proliferation.

Catching receiving errors before they enter available inventory prevents downstream fulfillment problems. Once bad data enters the system, it propagates through every subsequent transaction.

Picking and packing create their own issues. Wrong items ship, partial shipments aren’t recorded, returns sit in staging areas for days before system updates. Workarounds that bypass standard processes because “it’s faster this way” create long-term data problems that are difficult to untangle later. These shortcuts save seconds per transaction while creating hours of reconciliation work downstream.

The impact of lagging data

Data lag amplifies every other problem.

Stock updates that take hours to sync across channels, manual spreadsheet updates, and multiple warehouses or 3PLs without real-time visibility mean you’re operating on stale information rather than current facts. When the morning shift processes returns into one location and the evening shift checks a different location, the disconnect can persist for weeks.

This is how phantom inventory happens.

The worst part: when forecasts and replenishment are built on unreliable data—inaccurate lead times, missing shrink adjustments, demand patterns you can’t trust—every decision becomes speculation rather than analysis.

Standardize the workflow before adding more tech

Technology doesn’t fix broken processes. It accelerates whatever process you have, which means it makes mistakes faster and at greater scale if the underlying workflow is flawed.

Document the standard workflow first: receive, inspect, label, putaway, pick, pack, ship, reconcile. This baseline makes exceptions obvious instead of invisible. When everyone knows what “right” looks like, deviations become identifiable problems rather than accepted variations.

SKU and location hygiene matters more than most operations acknowledge. Unique SKUs eliminate ambiguity. Consistent naming conventions prevent confusion. Proper barcodes enable scanning verification. Clear location logic—zone, aisle, shelf, bin—means items can be found quickly and returned to the correct spot every time.

Warehouses that rely on institutional knowledge instead of documented location systems face predictable problems during staff turnover or vacations: pick times increase, training takes longer, and errors multiply.

Build verification checks where errors typically occur.

Scan verification at receiving catches problems before they propagate through subsequent transactions. Exception queues for damaged, missing, or unscannable items prevent problems from being forced into the system just to clear a task. Most operations skip these verification steps because they add time to familiar workflows. This resistance is where accuracy programs typically fail.

Linnworks demo: how to master inventory management

Centralize stock and automate updates across all your sales channels effortlessly.

Practical steps to improve accuracy

Cycle counting detects discrepancies faster than annual physical inventory counts. Daily counts detect problems within 24 hours, limiting the number of transactions that need investigation when errors surface. Weekly counts require reviewing five to seven days of activity to identify root causes, making diagnosis harder and corrections slower. Yes, daily counts are better, but if you can only get buy-in for weekly, start there.

Count high-impact items more often, low-impact items less often. Turn counting into routine warehouse operations rather than the once-a-year event that shuts everything down. Annual physical counts are visible and measurable, which makes them attractive to management, but visibility doesn’t equal effectiveness.

A process that happens once yearly can’t prevent daily errors. Annual counts create a perverse incentive structure: accuracy matters one day per year, which signals to teams that precision doesn’t matter the other 364 days.

Auditors may require annual counts for compliance, but treating them as your accuracy strategy confuses a regulatory checkbox with operational discipline.

Running audits

Run targeted audits on problem zones: fast movers, returns areas, high-shrink categories. When you compare system versus physical counts, log the root cause and fix the workflow that created the discrepancy—not just the number. Adjusting the inventory record without fixing what caused the error treats symptoms while ignoring disease.

Track every adjustment with a reason code and ownership. Damage, shrink, mis-pick, supplier short-ship. Limit who can make adjustments and require explanatory notes. This accountability surfaces patterns. If one person makes a disproportionate share of adjustments, that’s diagnostic information. If one location needs weekly corrections, the problem is likely the bin assignment or process, not the inventory.

Returns reconciliation breaks down at most operations. Items come back, someone receives them, but they hit “available” inventory before inspection. Separate “received” status from “restockable” status. Route returns through inspection first.

Otherwise you’re promising customers inventory that’s actually damaged or incomplete, which creates a new cycle of fulfillment errors.

Measure what matters: inventory record accuracy, shrink rate, pick accuracy, stockout frequency, backorder rate. These metrics indicate where problems exist and whether interventions are working. Track them to drive corrective action, not just to populate reports.

Keep inventory levels under control

Reorder points follow straightforward math: average demand during lead time plus safety stock. The challenge is maintaining current lead time assumptions. Supplier performance changes, shipping patterns shift, and reorder points calculated from 18-month-old lead times produce incorrect triggers.

Safety stock buffers against demand variability and supply uncertainty, but it’s expensive. Every unit of safety stock is cash sitting on a shelf “just in case.” Companies that implement blanket safety stock policies across all SKUs rather than adjusting for actual demand variability end up carrying unnecessary buffer on stable items while under-buffering volatile ones.

Apply more buffer to items with volatile demand or long lead times. Reduce buffer for stable items. Better yet, address lead time variability at its source—if safety stock exists to buffer a supplier with four to six week lead time variability, solving the supplier relationship may be more cost-effective than carrying permanent buffer inventory.

ABC analysis

ABC analysis applies the Pareto principle to inventory: classify SKUs by their contribution to revenue or volume, then allocate control effort accordingly. High-value A items justify frequent cycle counts and strict approval processes. Low-value C items can use lighter controls without material risk to the business.

Counting A items weekly versus monthly matters because high-velocity SKUs accumulate errors faster—more transactions mean more opportunities for discrepancies. This focused approach prevents spreading limited resources across all SKUs equally, which means spreading them too thin to be effective anywhere.

Watch inventory turnover and aging inventory reports. Turnover indicates whether stock is moving efficiently relative to sales. Aging flags cash tied up in slow movers and dead stock. Both inform purchasing decisions before small problems become large ones. Companies that ignore aging reports can accumulate excessive inventory on low-velocity items because automated reorder rules continue triggering without considering actual movement.

Align inventory targets to service level expectations. Define what “in stock” means for different item categories—perhaps 95% fill rate on A items, 90% on B items, 85% on C items. Build replenishment rules to hit those targets without overbuying.

This prevents both stockouts that damage customer satisfaction and excess inventory that drains working capital.

Linnworks demo: how to master inventory management

Master inventory management with Linnworks. Centralize stock and automate updates across all your sales channels effortlessly.

Where technology actually helps

Real-time inventory sync across channels prevents overselling because allocation updates immediately when orders are placed, rather than waiting for batch updates that may run hours or days behind actual transactions. This creates one source of truth for available, allocated, and inbound stock, eliminating phantom inventory.

The automation worth investing in eliminates manual data entry steps where errors typically occur: receiving scans, pick confirmations, and system-to-system integrations. Stock sync across channels, replenishment suggestions based on defined rules, exception-based alerts for low stock or demand spikes. Every manual update creates an opportunity for error. Effective automation removes those opportunities systematically.

For 2026, watch AI for anomaly detection and demand forecasting, improved IoT and scanning for faster transactions, and workflow automation that catches errors before they become problems. These technologies are maturing from interesting to genuinely useful for mid-market operations.

What to look for in software

For accuracy: barcode scanning, location and bin tracking, audit trails and adjustment controls, role-based permissions. Barcode scanning reduces keystroke errors and speeds transaction processing. Role-based permissions prevent unauthorized inventory adjustments that bypass approval workflows and hide discrepancies. These aren’t optional features—they’re fundamental controls for maintaining data integrity.

For inventory control: reorder points and safety stock rules, demand forecasting or integrations that support it, reporting for turnover and aging inventory. Good software makes these calculations automatic and surfaces exceptions that need human judgment.

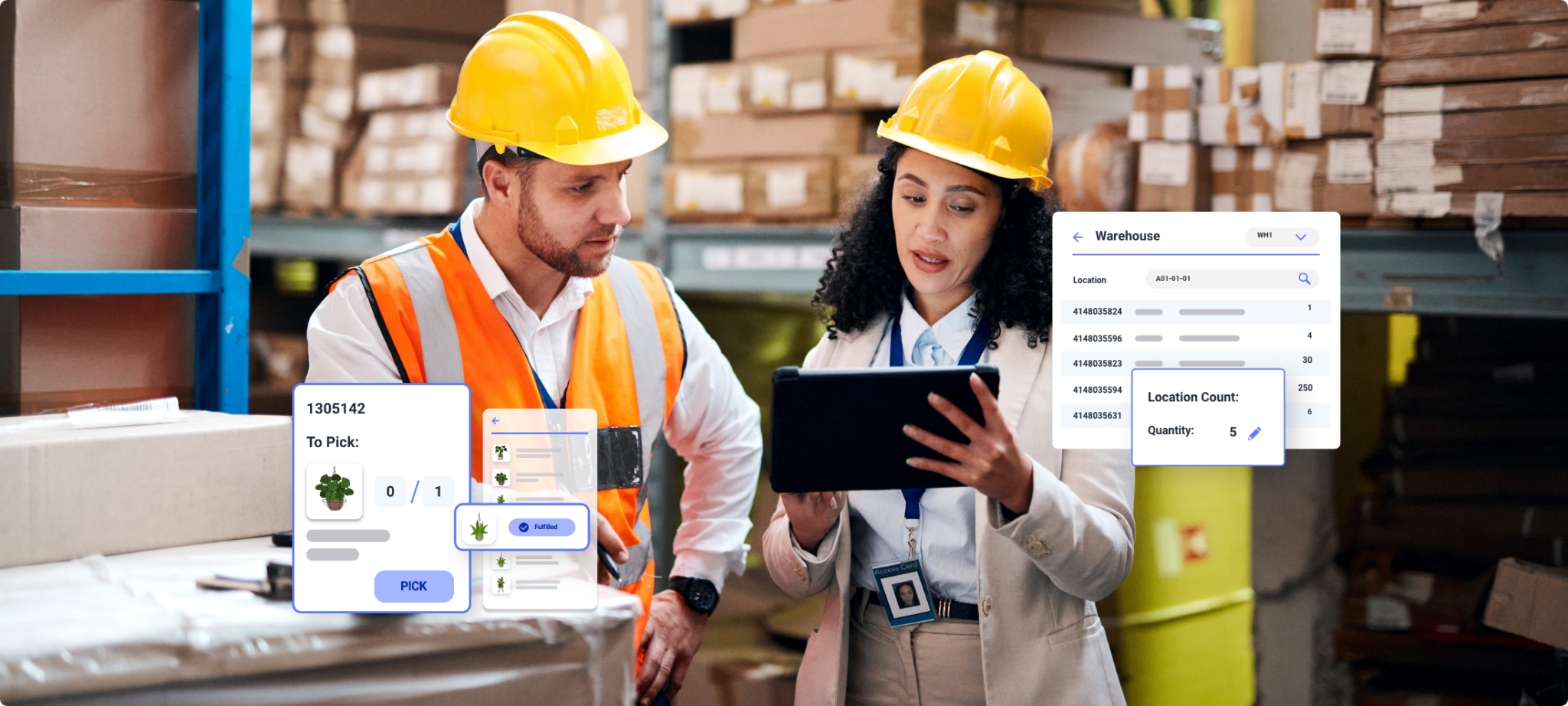

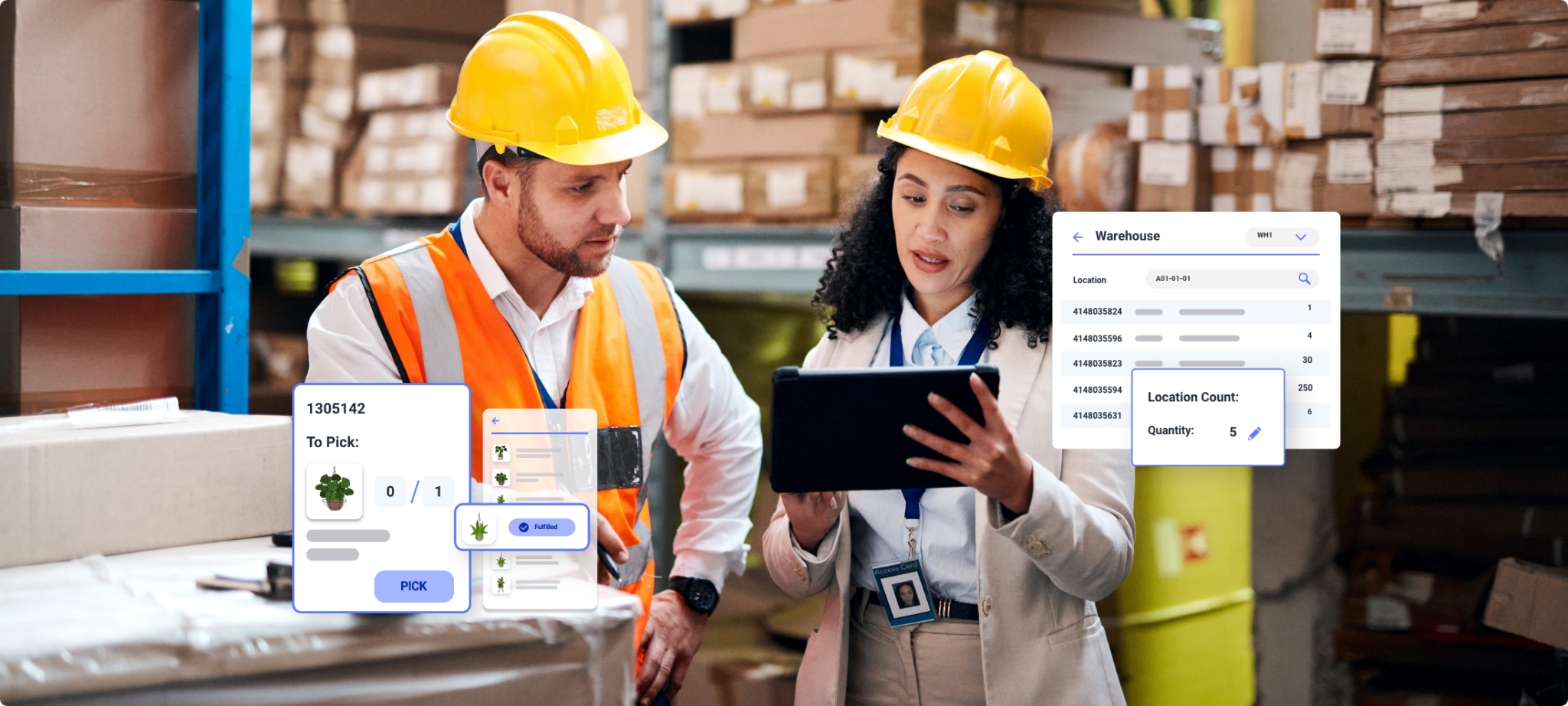

Linnworks delivers these capabilities through connected commerce operations that sync inventory across every sales channel in real time. The platform’s rules engine automates replenishment triggers based on the parameters you define, while maintaining audit trails for every adjustment. Location tracking works across multiple warehouses and 3PLs, creating the single source of truth needed to prevent phantom inventory and overselling.

When it’s working right, you see fewer manual updates, faster reconciliation, better visibility across warehouses and 3PLs. Teams spend less time firefighting data issues and more time improving operations.

That’s the outcome Linnworks is built to deliver—not just inventory management software, but the operational infrastructure that makes accuracy sustainable at scale.

A 30-day action plan

Week 1: Baseline and cleanup Pick 20 to 50 priority SKUs—your A items. Fix the SKU data, verify locations, clean up labeling. Lock down adjustment permissions. This creates accountability and provides a manageable scope to prove the concept works before expanding.

Week 2: Start cycle counting and verification checks Implement scan checks at receiving and picking. Set a cycle count cadence for those A items. Week 2 typically reveals resistance to verification steps because scanning every item at receiving and picking adds time to familiar workflows. This resistance is where most accuracy programs fail—not from technical problems, but from abandoning controls that feel slow initially. Address this resistance directly: explain that the added time at transaction prevents hours of reconciliation later.

Week 3: Replenishment rules and thresholds Define reorder points for priority SKUs based on current sales data and verified lead times. Add safety stock only where demand or supply variability justifies it. Resist the urge to buffer everything. Defining reorder points surfaces political questions about who owns those decisions and how to handle disagreements about lead times or demand assumptions. Resolve governance before building rules, or you’ll spend weeks debating every parameter.

Week 4: Automate reporting and exceptions Set up weekly reviews of inventory record accuracy and shrink. Create alerts for anomalies and low stock. Expand the program to the next tier of items. By now you’ll have learned what’s working and what needs adjustment. Use that feedback to refine the approach before scaling further.

Inventory and warehouse management savings calculator

Uncover the cost of your mis-ships, out of stocks and lack of labor efficiency with our inventory management savings calculator.

The bottom line

Standard processes and regular cycle counts drive accuracy. ABC analysis, smart reorder points, and intentional safety stock keep inventory levels under control. Technology reduces manual work and catches errors, but only after you’ve fixed the underlying workflows.

Daily discipline beats annual heroics. Operations showing 94% accuracy might seem acceptable until you calculate absolute numbers—6% error across 50,000 SKUs means 3,000 incorrect records affecting order fulfillment daily. That’s not a rounding error. That’s systematic dysfunction.

Start by auditing current accuracy. Identify the three biggest error points—typically receiving, returns, and adjustments. Fix those three things before trying to fix everything. Every improvement in accuracy produces better data, and better data enables inventory levels that support growth instead of constraining it.

The operations that get this right don’t have perfect systems. They have disciplined processes, routine verification, and the willingness to fix workflows instead of just adjusting numbers. Accuracy becomes sustainable when it’s built into how work gets done, not treated as a special project that happens once and gets celebrated.

FAQ

The most effective inventory management techniques for improving inventory accuracy include regular inventory audits through cycle counting, standardized warehouse operations with barcode scanning, and disciplined adjustment controls with reason codes. Cycle counting detects discrepancies faster than annual physical inventory counts by continuously verifying inventory records against actual stock levels. Implementing scan verification at receiving and picking reduces keystroke errors in your inventory management system. Tracking all inventory adjustments with ownership and reason codes (damage, shrink, mis-pick) surfaces patterns that indicate systemic workflow problems. These inventory management best practices work together to maintain high inventory record accuracy, which directly impacts order fulfillment reliability and customer satisfaction.

Inventory management software improves warehouse operations by automating stock control processes that typically cause errors when performed manually. Real-time inventory tracking across channels prevents overselling and eliminates phantom inventory through immediate allocation updates. Barcode scanning support reduces data entry errors during receiving and picking. Role-based permissions prevent unauthorized inventory adjustments that bypass approval workflows. Automated replenishment suggestions based on reorder points and safety stock rules reduce excess inventory while preventing stockouts. The perpetual inventory system enabled by good software provides continuous visibility into inventory levels, aging inventory, and inventory turnover—allowing you to make data-driven decisions that optimize inventory costs and improve operational efficiency across your entire supply chain.

Best practice in inventory management applies ABC analysis to allocate control effort based on each inventory item’s contribution to revenue or volume. A items represent high-value stock that justifies frequent cycle counts (daily or weekly), strict approval processes for adjustments, and tight reorder point management to maintain optimal inventory levels. B items receive routine inventory audits and standard warehouse management controls. C items use lightweight processes since their low value doesn’t justify intensive oversight—simplified replenishment rules and less frequent inventory counts. This inventory management technique follows the 80/20 principle: focusing resources on high-impact items improves inventory accuracy where it matters most for customer demand fulfillment and customer satisfaction, while preventing wasted effort on low-value stock control.

Reducing excess inventory while maintaining customer satisfaction requires balancing optimal inventory levels with service level targets. Start by analyzing sales data to set accurate reorder points based on actual customer demand and verified lead times, rather than using blanket safety stock policies. Use inventory turnover and aging inventory reports to identify slow-moving stock before it becomes dead inventory. Implement ABC analysis to apply appropriate inventory control to different item categories—maintain higher stock levels and tighter management on A items that drive customer satisfaction, while reducing buffer on stable C items. Effective inventory management software with demand forecasting capabilities helps predict customer demand patterns more accurately. Regular inventory audits ensure your inventory data remains reliable for making these decisions. This approach optimizes inventory costs without increasing stockout risk on items critical to order fulfillment.

Essential inventory management system features for effective inventory control include barcode scanning for accurate inventory tracking, location and bin tracking for organized warehouse layout management, audit trails that document all inventory adjustments, and role-based permissions that prevent unauthorized changes to inventory records. For managing inventory levels, look for automated reorder point calculations, safety stock management, and reporting for inventory turnover, aging inventory, and fill rates. The best inventory control systems provide real-time visibility across multiple warehouse operations and integrate with your supply chain management tools. These capabilities enable the inventory management process fundamentals: maintaining inventory accuracy, preventing excess inventory, optimizing inventory costs, and ensuring reliable order fulfillment. Efficient inventory management software eliminates manual data entry steps where errors typically occur, improving both operational efficiency and inventory data reliability.