Improve your warehouse inventory management: 10 ideas for 2025

Managing a large warehouse inventory can be a daunting task for any business. A successful approach directly impacts your ability to maximize productivity, save money, and maintain inventory accuracy. For ecommerce businesses, effective warehouse management is often the critical difference between success and failure.

As you prepare for 2026, updating your strategy with modern tools is essential. This article will provide 10 practical ideas for mastering your warehouse operations and show you how technology can support you along the way.

Inventory management savings calculator

What is the current cost of your mis-ships, out of stocks and lack of labor efficiency?

What is warehouse inventory management?

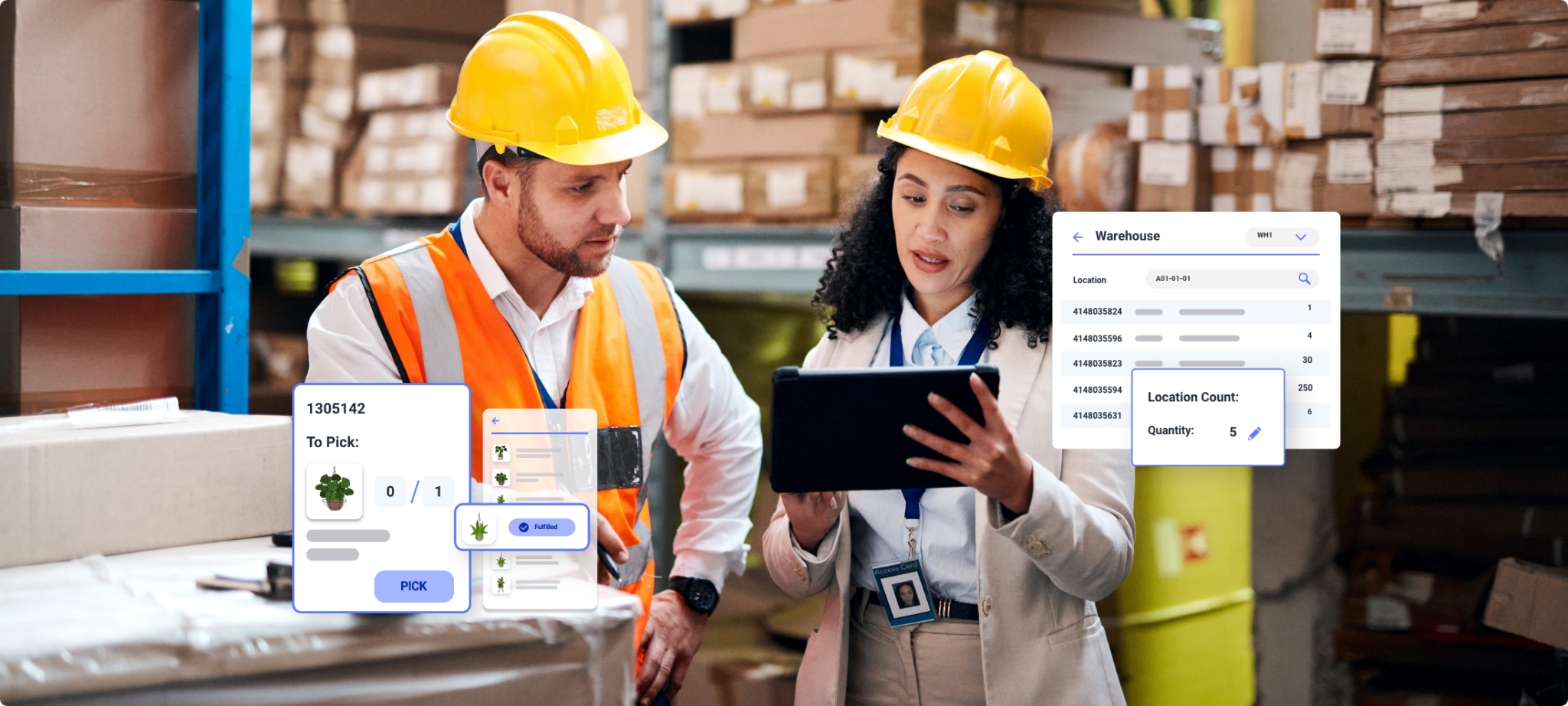

Warehouse inventory management is the process of tracking, organizing, and optimizing stock within a warehouse. It ensures accurate inventory levels, efficient space utilization, and timely order fulfillment. By leveraging software and tools like barcoding, you can minimize errors and improve your operations.

This process includes:

- Tracking product locations

- Handling order fulfillment

- And forecasting inventory levels

Furthermore, it entails overseeing:

- Warehouse staff

- Material handling

- And warehouse space to ensure efficiency and productivity.

Now, you might be wondering, how in the world can you keep tabs on all these at once? In almost every modern business, a warehouse inventory management system is the backbone of these operations.

Warehouse management software provides business owners with real-time data on inventory levels, quality control, profitability, and more. A warehouse management system is instrumental in reducing human error, improving order fulfillment times, and maximizing warehouse usage.

Warehouse management vs. inventory management

It’s common to get the terms warehouse management and inventory management mixed up, but they refer to two distinct aspects of the supply chain process.

Let’s start with warehouse management . This involves managing the warehouse layout , the storage of goods, and ensuring that warehouse operations run smoothly.

The responsibility falls mainly on the warehouse manager, who ensures that goods are properly stored, processed, and shipped.

On the other hand, inventory management involves tracking, controlling, and managing the actual items or products that are being stored and moved around in your warehouse.

The primary tool for inventory management is inventory management systems (IMS) like Linnworks, which give you a clear picture of what items we have, where they are located, and when they need to be restocked or moved.

While they are different, both are crucial aspects of a well-oiled supply chain and proper warehouse inventory control.

What are the common challenges of warehouse inventory management?

Despite the pivotal role it plays in supply chain operations, businesses often grapple with numerous challenges. Let’s take a look at some of the most common issues.

1. Inventory inaccuracy

Inventory inaccuracy is one of the most prevalent issues in warehouse inventory management. It can result from data entry errors, damage or loss, or discrepancies between actual stock and recorded stock.

These inaccuracies can lead to problems like stockouts and overstocks, both of which impact your bottom line and customer satisfaction.

2. A lack of visibility

Another significant challenge is a lack of visibility. Without a clear view of your inventory (especially when managing multiple channels ), you may not know what products you have, where they are located, or when they need replenishment.

This lack of visibility can lead to poor decision-making and missed opportunities.

3. Inefficient warehouse layout

An inefficient warehouse layout is another common stumbling block. Poorly organized warehouses can hinder the movement of goods and personnel, leading to reduced productivity and increased chances of error or injury.

Optimizing your warehouse setup for flow and accessibility can significantly enhance efficiency and worker safety.

4. Relying on manual processes

Lastly, reliance on too many manual processes can severely disrupt your warehouse operations. Manual data entry and physical counts are time-consuming and prone to errors.

Implementing automation through warehouse management systems can help to streamline processes, reduce human error, and increase efficiency.

Navigating these challenges may seem daunting, but fear not – there are solutions and best practices available to address each of these issues effectively. Let’s explore some of them next.

Choosing the right warehouse inventory management software

Reliance on manual processes is a major challenge that can disrupt warehouse operations, as it’s both time-consuming and prone to error.

Investing in the right warehouse inventory management software is the most effective way to solve this, transforming your operations to be more efficient and streamlined.

A robust software solution reduces human error, saves time, and gives you a clear, real-time view of your stock.

When evaluating software, look for these key features:

- Real-time inventory tracking: The system should give you a live picture of your stock levels across all locations and sales channels. This is critical for preventing overselling and knowing when to reorder.

- Multi-channel integration: For ecommerce businesses, the software must integrate seamlessly with your marketplaces and online stores. This ensures that quantities listed on all platforms are accurate.

- Barcoding and labeling: Effective software should support barcoding to minimize errors during picking and receiving. Look for features that allow you to print custom product and location labels to fit your specific needs.

- Forecasting and reporting: To make informed decisions, your software should provide tools for forecasting inventory levels and reporting on sales patterns. This helps you identify high-selling products and optimize stock placement.

Understanding warehouse inventory management systems (WMS)

While inventory management software focuses on tracking products, a Warehouse Management System (WMS) is a broader solution that assists in and optimizes day-to-day warehouse operations.

A WMS provides real-time data to guide everything from inventory receiving and storage to picking, packing, and shipping. It is the backbone of a modern warehouse, designed to maximize both warehouse space and labor efficiency.

There are several types of systems to consider:

- Standalone systems: These are specialized WMS platforms focused exclusively on warehouse operations. They often offer deep functionality but require integration with your other business software.

- Integrated ERP modules: Many Enterprise Resource Planning (ERP) systems include a WMS module. This is a good option if you want a single, unified system for all business operations, from accounting to inventory.

- Cloud-based vs. On-premise: Cloud-based (SaaS) systems are hosted by the vendor and are typically more flexible and scalable. On-premise systems are hosted on your own servers, offering more control but requiring a larger upfront investment.

Choosing the right WMS is a strategic decision that depends on your business size, complexity, and growth plans.

The right system will reduce human error, improve order fulfillment times, and maximize your warehouse usage.

What are the benefits of good warehouse inventory management?

The benefits of warehouse management software extend far beyond just keeping your inventory in check – they can boost your bottom line, enhance customer satisfaction, and improve overall efficiency.

Let’s delve into some specific advantages.

Makes inventory tracking easy

When set up in the right way, tracking inventory becomes a breeze. By using inventory management systems like Linnworks, you can keep real-time tabs on your stock levels, where you store inventory, and the status of orders.

(See this in action with our self-guided tour of the platform!)

Boosts warehouse productivity

A well-managed warehouse is a productive warehouse. Proper warehouse inventory management means less time spent searching for items, fewer misplaced or lost stock instances, and fewer instances of overstocking or stockouts.

Increases customer satisfaction

Believe it or not, effective warehouse inventory control can significantly boost customer satisfaction. We’d even argue you can draw a straight line from good warehouse processes to profitability. How so?

When inventory is accurately tracked and managed, you can ensure that the right products are available when customers need them.

Faster picking and packing process

An organized warehouse leads to faster picking and packing. When items are appropriately labeled and stored in logical, easy-to-access locations, warehouse managers and workers can quickly locate and pick items for orders.

More efficient warehouse operations

All these benefits culminate in a more efficient warehouse operation overall. With:

- Easy inventory tracking

- Increased productivity

- Happier customers

- And faster processing times

Your warehouse becomes a well-oiled machine that operates seamlessly and efficiently.

Practical warehouse inventory management tips

1. Regular upkeep

Effective warehouse inventory management kicks off with consistent maintenance and inspection. A pivotal first step to managing warehouse inventory is ensuring your warehouse meets your current standards.

How does this look in practice? It’s about being proactive and regularly auditing your warehouse operations and organization. Ask yourself:

- Is your inventory positioned so that warehouse staff can easily and safely access it?

- Are your “hot” SKUs conveniently located between waist and shoulder height for quick picking?

- Have you designated an area in your warehouse specifically for damaged items?

- Are these damaged items attended to daily?

Ensure your warehouse manager has a daily checklist and hold them accountable for maintaining the warehouse standards. This ongoing maintenance and accountability are crucial for managing inventory effectively.

2. Know your high sellers

Next, place your high-volume items closer to the shipping area. Make sure they are easily accessible – you’ll eliminate a lot of unnecessary labor time.

If you want to pinpoint your high sellers, use a tool like Linnworks reporting . This feature allows you to pull aggregated data using advanced settings. You can filter by brand, class, and supplier to help you notice patterns and make more informed decisions about warehouse placement.

3. Maximize your software’s features

Once you have a warehouse management system, the next step is to use it to its full potential. Go beyond basic inventory tracking and explore its advanced features. Use reporting tools to analyze sales data and identify your “hot” SKUs, just as you would with Linnworks reporting.

Set up automated rules for reordering low-stock items and ensure your team is fully trained on all features. Maximizing your software turns it from a simple tracking tool into a strategic asset for your business.

4. Utilize cycle counts

Here’s an insider tip — don’t hold your breath waiting for that annual physical inventory count to take stock of where your inventory stands. Instead, employ the cycle counting strategy to maintain an ongoing inventory audit.

Now, you might be asking, “ What is cycle counting ?” Cycle counting is a savvy approach to perpetual inventory management. Instead of tackling the entire inventory in one go, you focus on smaller subsets of inventory, counting them in waves over a period of time.

The real beauty of cycle counts is in their frequency and scope. Regularly going through all your locations every quarter creates a more accurate, up-to-date picture of your warehouse inventory. It’s like getting a quarterly health check-up for your warehouse!

5. Label everything

Do you have any product in your warehouse without labels? Put labels on them to make it easier for pickers to choose the right inventory. Either devise your own labeling system and purchase thermal printing labels to print them on, or you can use a labeling software.

Linnworks allows you to print out your product and location labels, and also helps you to determine what gets put on your labels to customize them to fit your exact needs.

6. Implement quality control

Avoid fixing your mistakes after the fact by double-checking your orders. This is called quality control and it adds another layer of responsibility (and almost always results in higher customer satisfaction). This process usually involves checking a picked item against an order to ensure it’s the correct SKU and quantity.

Meanwhile, QC can also check the item for damage to ensure it is being shipped in its advertised condition and that the customer receiving it will be happy.

7. Practice priority picking

A nice trick we’ve learned over the years is to create colored orders or pick lists.

These will help your material handlers identify the products that go to your most valuable customers because they can observe the color priority.

8. Work on warehouse organization

You know how in any place that houses a large inventory of product for rent or sale (like big box stores or supermarkets), everything is neatly categorized and the sections are clearly labeled to assist customers in finding what they’re looking for?

That’s super convenient for warehouse workers, too!

Make signs and labels to direct your personnel through your warehouse and help them find the inventory quickly, easily, and ideally without continually bothering supervisors by asking for directions.

Master your warehouse inventory management with Linnworks

Effective warehouse inventory management has a significant impact on the way your ecommerce business functions—and the results it achieves. By implementing these ideas, and embracing the right technology along the way, you can turn your warehouse inventory management processes from a headache to a value creator.

Ready to discover the power of Linnworks? Book a free demo today and find out how our solution can level-up your approach to warehouse inventory management for the better.

Ready to discover the power of Linnworkstgfr? Book a free demo today and find out how our solution can level-up your approach to warehouse inventory management for the better.

Warehouse inventory management FAQs

Warehouse inventory management is the process of supervising and coordinating inventory, warehouse floor space, and logistics operations in a warehouse setting.

This includes tasks like tracking inventory levels, handling orders, managing warehouse storage, and ensuring the efficient movement of goods within the warehouse.

Effective warehouse inventory management relies on three core areas: physical organization, consistent processes, and technology. A well-organized warehouse layout improves the flow of goods and increases efficiency. This is supported by key processes like regular cycle counting, clear product labeling, and quality control checks, which ensure inventory accuracy and customer satisfaction. Tying it all together, a dedicated warehouse management system is crucial for automating tracking, reducing human error, and providing real-time data on stock levels.

A warehouse management system (WMS) is a software solution that assists in the day-to-day operations of a warehouse.

It guides inventory receiving and storage, optimizes the picking and shipping of orders, and advises on inventory replenishment.

A WMS helps manage resources and warehouse space to improve efficiency and productivity by employing real-time data.

An inventory management system is used to track goods across the supply chain. It monitors inventory levels, sales, orders, and deliveries to ensure accurate inventory quantities.

By using such a system, businesses can reduce the risk of product overstock and outages, ultimately saving costs and increasing customer satisfaction.

Linnworks offers an integrated warehouse inventory management software solution.

It combines the benefits of warehouse and inventory management systems, enhancing efficiency and productivity.

Its core features include real-time inventory tracking, efficient warehouse space utilization, automated processes, and comprehensive onboarding and training.

Optimizing the layout of your warehouse is crucial to improve picking efficiency, reduce handling costs, and maximize the use of available space.

A well-organized warehouse can facilitate smoother and faster movement of goods, increase worker productivity, and reduce the risk of accidents.

Cycle counting is an inventory management procedure where a small subset of inventory in a specific location is counted on a specified day.

It’s an alternative to complete, wall-to-wall physical inventory counts and can be done more frequently. Regular cycle counts can improve inventory accuracy and help identify and resolve discrepancies early.