Inventory planning guide for ecommerce businesses

Today’s ecommerce landscape is more than just transactions – it’s about fostering genuine connections with customers and ensuring they come back for more.

But behind the seamless shopping experiences and rapid delivery times is the often-forgotten, inventory planning system.

The inventory planner holds the power to elevate customer satisfaction and guard your profits. Yet, mastering it isn’t always straightforward.

This guide aims to demystify the world of inventory planning, presenting actionable strategies and insights for ecommerce store managers, owners, and retail decision-makers.

With a well-oiled inventory planning system, not only can you navigate challenges that could dent your bottom line, but you can also elevate your brand in the crowded marketplace.

Dive in to harness the full potential of this inventory planning tool for your business.

The basics of inventory planning

Inventory planning isn’t just a background task – it’s front and center in shaping customer experiences and driving sales.

An inventory planner is more than ticking boxes and tallying numbers; it’s about ensuring your customers find what they want when they want it, and it requires efficient inventory planning.

1. Definition and importance

So, what exactly is inventory planning?

At its core, it’s the process of making sure you have the right products available at the right times, ensuring you manage inventory effectively. It’s a balancing act, aligning what you offer with what your customers demand. Proper inventory planning makes all the difference.

Jill Liliedahl, Vice President of Revenue at Inventory Planner, gives us some perspective, reminding us that it’s not merely about stocking up – it’s about being strategic and focusing on items that meet your inventory needs and have the most potential to boost profits.

2. Objectives of inventory planning

At its heart, inventory planning has some clear aims:

- Minimize stockouts: no one likes seeing an ‘out of stock’ sign. It’s about being proactive, and predicting what your customers will want next

- Reduce excess inventory: holding onto stacks of unsold items? That’s capital sitting idle. Streamlining your inventory means freeing up valuable resources, which can be better utilized elsewhere

- Optimize costs: ever heard of GMROI? It’s a tool that shows how much return you’re getting from each item in your inventory – simply divide your gross margin by your average inventory costs. Combine that with stock-turn insights, and you’re equipped to make savvy business decisions.

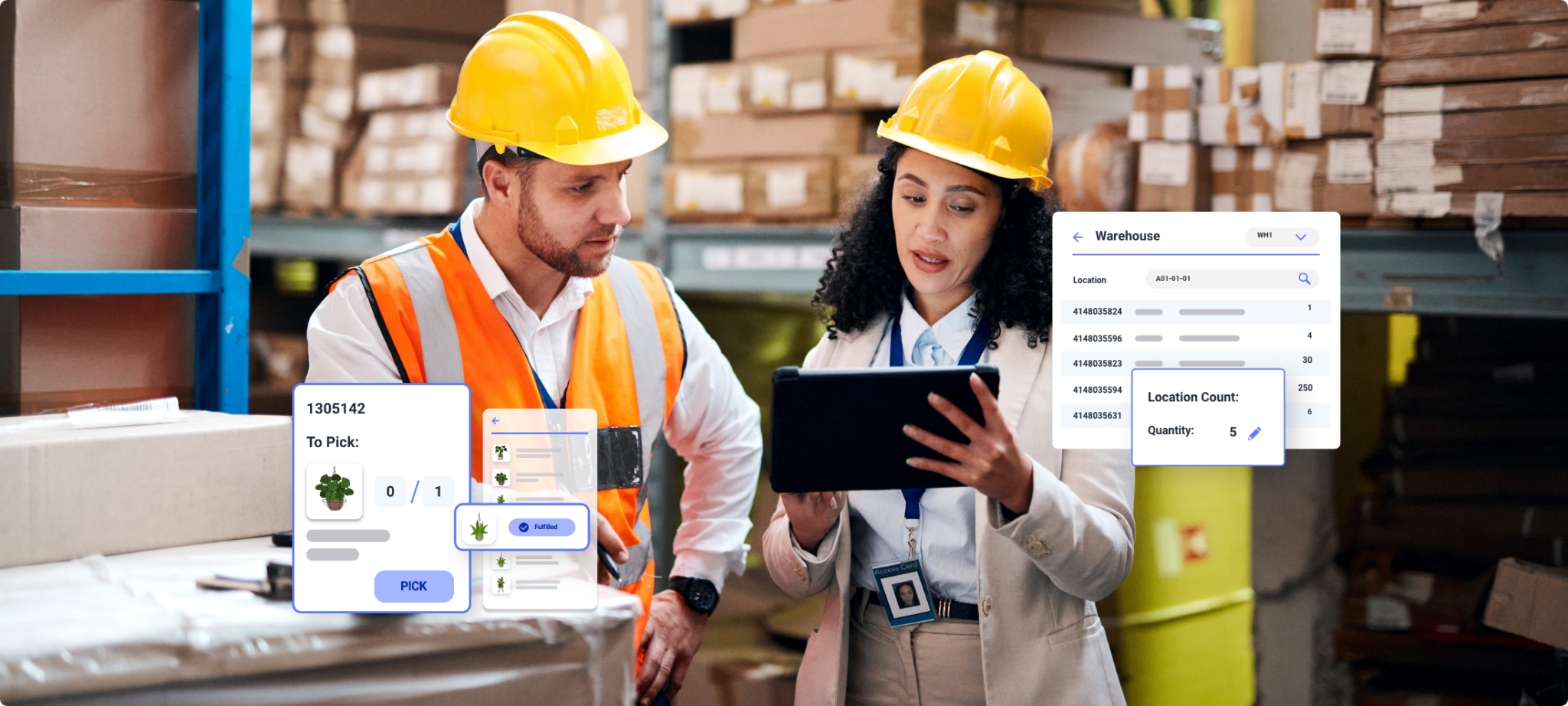

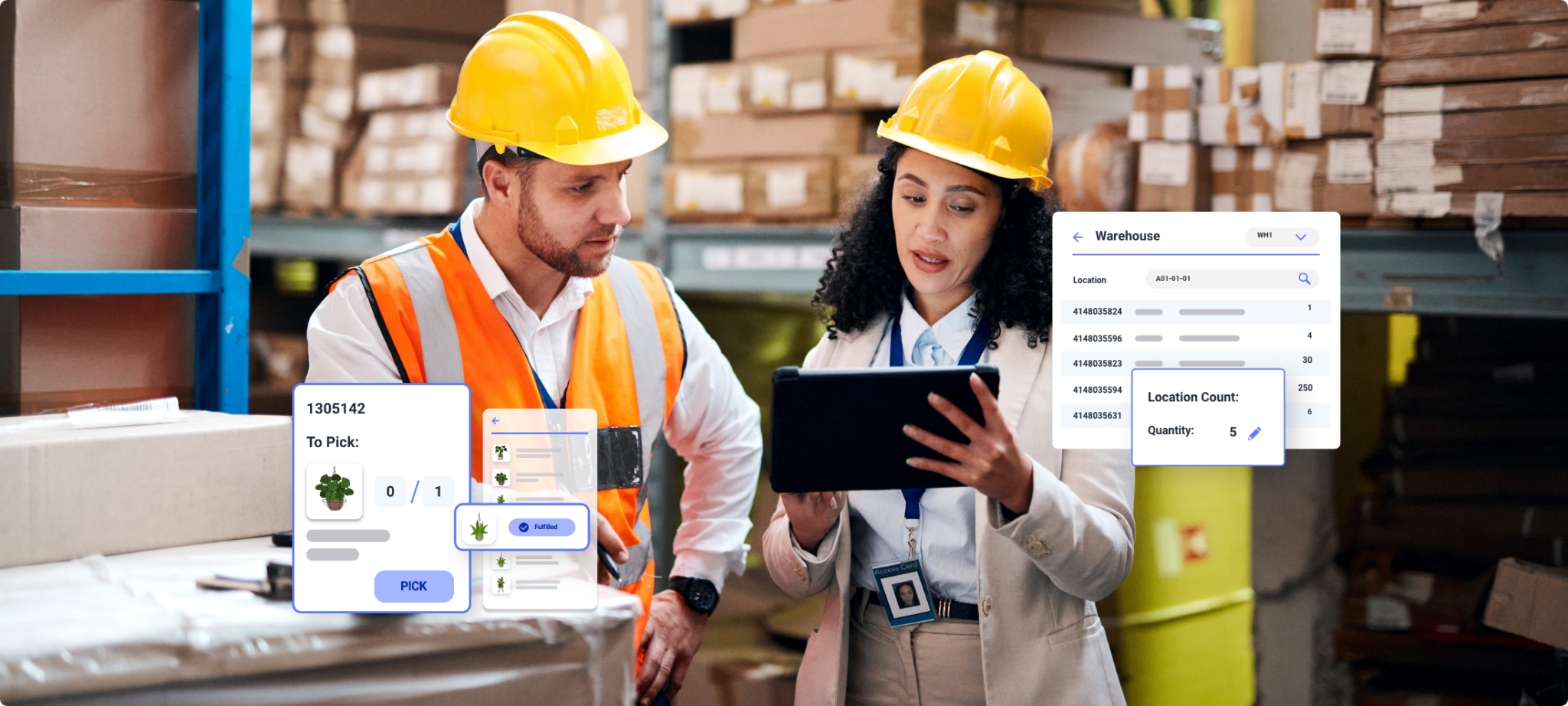

Linnworks demo: how to master inventory management

Centralize stock and automate updates across all your sales channels effortlessly.

Jill’s advice? Find that sweet middle ground in your inventory.

If your stock flies off the shelves too quickly, you might not be keeping up with demand. But if products linger too long, you’re likely overstocked. It’s about tuning into your business’s unique rhythm, aligning with your product type and cash flow.

And let’s not forget – the stakes are high. A misstep in inventory can lead to frustrated customers, missed sales, overstock issues, or poor cash flow.

In an industry where customer loyalty can hinge on product availability, getting inventory and demand planning right is both an art and a science.

Challenges and solutions in inventory planning

The inventory planning process – though essential – comes with its own set of intricacies.

While you could simply view past data and project it onto the future, there are nuanced hurdles to cross and strategies to perfect. Optimize inventory allocation routes to ensure that stock reaches where it’s most needed in the most efficient way.

Let’s take a look at the most common challenges of inventory planning processes faced by retailers and how to maneuver around them.

1. Demand variability

Challenge: from seasons to trends, demand isn’t static.

Taking last year’s figures and just pasting them onto the current year is oversimplifying. Factors like market changes, new competitors, or evolving consumer behaviors can disrupt previous patterns.

Solution: regularly analyze your demand data.

For seasonal items, look beyond just year-on-year trends, and consider factors that might change this year. For non-seasonal items, review the past three to six months. And for trendy items? Keep a close eye on shorter data intervals, like every two to four weeks.

But always remember, while short-term spikes are enticing, long-term stability and understanding your inventory needs are key.

2. Lead time uncertainty

Challenge: The best-laid plans can go awry if stocks aren’t ready when needed.

This is particularly true when dealing with international vendors or an intricate supply chain. Delays in receiving products can severely dent your inventory planning.

Solution: communication is king.

Regularly update your vendors on expected demand for the upcoming months. Foster strong vendor relationships to make production schedules ensure stock readiness. Especially with international vendors, a heads-up on projections helps them prep, bridging the lead time gap.

3. Excess inventory

Challenge: over-optimistic projections can lead to bulging inventories.

Not only does this tie up capital, but it also consumes valuable storage space.

Solution: as Jill Liliedahl points out, it’s tempting to jump on trends and stock up, but watchfulness is crucial.

Focus on those products genuinely driving your revenue. And yes, automate! As businesses scale, manual processes become clunky and error-prone.

Accurate inventory management software like Linnworks can illuminate the big performers, aiding in sharper, data-backed decisions.

4. Location and channel differences

Challenge: what works in one sales channel or location may falter in another.

Poor inventory planning at this stage can result in significant losses. As you expand, this differentiation can complicate inventory planning.

Solution: every new location or sales channel should have a tailored approach.

Dive into specifics – competition, local preferences, pricing – and adjust your inventory strategy accordingly.

5. Complex supply chain management

Challenge: recent fluctuations in global supply chains, from material shortages to economic shifts, have turned inventory planning on its head.

Often, smaller businesses can feel they’re at the mercy of larger manufacturers or distributors.

Solution: diversify.

Instead of relying solely on distant suppliers, consider local or nearshore options. This not only reduces lead time but also offers a safety net against global disruptions.

6. Reliable data collection

Challenge: without accurate data, inventory planning can quickly become a game of guesswork.

Manual processes, while traditional, can lead to inefficiencies and errors.

Solution: enter the era of automation.

Automated inventory systems, with real-time tracking and analytics, provide a clearer and more granular picture of where stock stands, cutting down errors and ensuring availability.

Trusting the tech means you’re always a step ahead.

Inventory planning is as much about understanding your market and customers as it is about physically counting stock. As challenges arise, adapting with informed strategies ensures your ecommerce venture thrives in any scenario.

Inventory and warehouse management savings calculator

Uncover the cost of your mis-ships, out of stocks and lack of labor efficiency with our inventory management savings calculator.

Steps in effective inventory planning

Inventory planning is a meticulous dance, synchronizing what you need with when you need it, all while keeping costs at bay.

To make this happen seamlessly, businesses can follow specific steps that offer clarity and optimize current inventory planning methods.

1. Demand forecasting

Predicting what your customers will want, and when, is no easy feat.

Yet, it’s the bedrock of inventory planning.

By analyzing historical sales data and keeping an eye on current market trends, businesses can forecast future sales demand with increased accuracy. This not only prepares you for surges in customer demand, but also prevents overstocking, ensuring resources are used effectively.

2. Safety stock calculation

Uncertainties are part and parcel of the retail world.

Safety stock acts as a buffer against those unpredictable factors like sudden spikes in demand or supply chain disruptions. It’s essentially extra stock that’s kept on hand to prevent stockouts.

Calculating the right amount of safety stock considers factors like lead time variability and demand fluctuations. It’s your insurance against the unexpected.

3. Lead time management

From the moment you place an order to the instant it’s in your hands, that duration is lead time.

It plays a pivotal role in determining how much inventory you should have on hand.

Longer lead times could mean higher safety stocks, while shorter ones might allow for leaner inventories. Effectively managing lead time requires continuous vendor communication, monitoring transportation channels, and, importantly, understanding any seasonal impacts on delivery.

4. Reorder point determination

Knowing when to place an order is crucial.

The reorder point is that magic number at which you should order more stock. It’s not a mere hunch; it’s calculated.

Based on lead times and anticipated demand, the reorder point ensures that new stock arrives just as your safety stock is about to deplete, keeping the flow of goods smooth and preventing stockouts.

5. Economic order quantity (EOQ)

Think of EOQ as the sweet spot in ordering.

It determines the most cost-effective quantity to order, balancing ordering costs with storage costs. By using the economic order quantity model, businesses can ascertain the optimal order quantity that minimizes total inventory costs.

This model considers aspects like demand rate, order cost, and holding cost.

6. ABC analysis

At its core, ABC inventory analysis is a method to prioritize inventory items based on their importance to the business, segregating them into three categories: A, B, and C.

Breaking it down, ‘A’ items are high-priority ones, often having the highest value or impact on overall cash flow and business performance. These require close monitoring and tight inventory control.

‘B’ items sit in the middle ground, important but not as crucial as ‘A’ items. They often represent a balance of moderate consumption and value.

Lastly, ‘C’ items are the ones that, while necessary, have the least value and are plentiful in stock. They might be low-cost items that are ordered in bulk.

By categorizing inventory using ABC Analysis, businesses can allocate resources more efficiently, focusing their attention where it matters most and ensuring that critical items are always in stock.

Each of these steps in inventory planning offers businesses the tools they need to operate efficiently and meet customer demands.

By forecasting, preparing for uncertainties, and understanding the nuances of ordering and categorization, e-commerce businesses can thrive in an ever-evolving market.

Factors affecting inventory planning

Managing inventory is not just a numbers game. An efficient inventory management system can significantly streamline the process.

Various external and internal factors come into play that can affect how much stock you should keep, and when.

By understanding these dynamics, ecommerce businesses can navigate the complex waters of inventory process flow and inventory planning processes with a little more ease.

Seasonality and trends

A substantial part of inventory planning revolves around recognizing the cycles your products undergo, often based on historical data.

Seasonal demands, such as winter clothing in colder months or swimwear in the summer, require businesses to adjust their inventory levels accordingly.

On the flip side, trends, driven by popular culture, social media, or other rapid influences, can spike demand unpredictably. Ignoring these can lead to missed sales opportunities or overstocked items that lose their market appeal quickly.

Supplier relationships

Your supplier isn’t just another entity; they’re a critical partner in your inventory journey.

The reliability of a supplier, their lead times, and the quality of the goods they provide directly impact your inventory planning. If a supplier is known for late deliveries, it could mean you need to keep more safety stock, which might lead to increased holding costs. Strong, transparent relationships with suppliers can also lead to better negotiations on prices and priority during stock shortages.

The deeper the trust, the smoother the inventory process flow can be – a significant win for your business.

Market fluctuations

The market isn’t static; it’s an ever-evolving beast.

Economic changes, competitive strategies, regulatory shifts, or even customer preferences can lead to sudden fluctuations in the market.

For example, an introduction of a groundbreaking product by a competitor can reduce demand for your product overnight. On the other hand, positive publicity or a successful marketing campaign can lead to a surge in demand.

Be agile. Being attuned to the market’s pulse, using various inventory planning models, and adapting quickly, is crucial for successful inventory planning.

External disruptions

Sometimes, events entirely out of your control can throw a wrench in the works, affecting the overall holding costs.

Natural disasters like hurricanes, floods, or wildfires can disrupt both demand and the supply chain. Then there are geopolitical issues, strikes, or even global pandemics that can severely affect manufacturing and shipping.

It’s essential to have contingency plans for such unpredictable disruptions. This might include diversifying suppliers, having alternative shipping routes, or even insuring against certain types of business interruptions.

In the unpredictable world of retail, forewarned is forearmed.

By understanding these influencing factors and building strategies around them, ecommerce businesses can make informed decisions, ensuring that their inventory planning remains robust and resilient.

Linnworks demo: how to master inventory management

Master inventory management with Linnworks. Centralize stock and automate updates across all your sales channels effortlessly.

Technology and tools for inventory planning

Relying solely on manual inventory planning methods for inventory planning will lead to inefficiencies, mistakes, and missed opportunities.

Leveraging technology and tools not only simplifies this complex task but also offers precision and scalability.

Inventory management software

At the heart of streamlined inventory planning lies robust inventory management software.

Such software offers real-time insights into stock levels, automates reordering processes, and integrates seamlessly with sales channels.

With Linnworks, tracking inventory and automating reordering based on known sales frequency and volume is made easy for growing businesses. By removing the manual toil, retailers can divert their attention to strategic decision-making and growth initiatives.

As an additional benefit, this automation minimizes human error, ensuring that just the right amount of stock is ordered at the right time.

Demand forecasting tools

Understanding what lies ahead is crucial for effective inventory planning.

Demand forecasting tools are a type of inventory planning software that uses historical data, market trends, and predictive algorithms to project future demand.

Linnworks – apart from its inventory management capabilities – offers demand forecasting prowess. The central dashboard provides a real-time view of inventory performance across all sales channels.

By analyzing this historical data together, Linnworks can assist retailers in anticipating market movements, preparing them for seasonal spikes or downtrends, and ensuring that stock levels are always optimal.

Reporting and analytics

Knowledge is power, and in the realm of inventory planning software, this knowledge comes from data-driven insights.

Reporting and analytics tools delve deep into sales, stock movement, and customer behavior, offering retailers a granular view of their inventory’s performance. Linnworks’ intuitive dashboard provides clear and comprehensive insights into product performance, helping retailers avoid pitfalls like stockouts and overstocking.

By having this clear picture of inventory levels and performance metrics, retailers can make informed decisions, ensuring that their inventory strategy aligns with their business goals.

Tools like Linnworks are not just software solutions – they’re strategic partners in a retailer’s journey. By centralizing data, automating processes, and offering actionable insights, they empower ecommerce businesses to navigate the challenging waters of inventory planning with confidence and precision.

Inventory planning best practices

Navigating the intricate pathways of inventory planning can be a bit like crafting a perfect recipe. It requires a balance of the right ingredients, continuous taste-testing, and sometimes, a bit of culinary innovation.

Here are some of the tried-and-true practices that industry leaders swear by to keep their inventory management a notch above the rest.

Regular review and analysis

Think of your inventory plan as a living, breathing entity. It’s not something to set and forget.

Regular reviews are crucial. Why?

Because consumer demand is fluid, market conditions change, and the efficiency of operational processes can always be fine-tuned. Analyzing historical sales data, understanding product performance, and monitoring inventory turnover rates are essential.

By frequently checking in, you ensure that the blueprint of your own inventory system remains attuned to real-world scenarios, helping to ward off stockouts, reduce overstock, and increase profitability.

Collaboration and communication

Inventory planning isn’t just a task for the supply chain team. It’s a cross-departmental endeavor that necessitates robust communication.

Sales can provide insights into upcoming promotions that might spike demand. Marketing can give heads up on campaigns that might affect product visibility and interest. Meanwhile, procurement can chip in with updates on supplier dynamics.

Ensuring that all these departments collaborate, share data, and keep open lines of communication is essential. When everyone is on the same page, inventory plans are more resilient, adaptable, and successful.

Continuous improvement

In the world of inventory planning, good enough is never truly enough.

There’s always room to grow, adapt, and optimize. This requires a mindset that doesn’t just settle but seeks constant enhancement.

Maybe it’s experimenting with a new forecasting tool, dabbling in a different inventory classification method, or tweaking the reordering strategy based on fresh insights. The idea is to always be on the lookout for opportunities to better the system. Adopting a Kaizen approach, a Japanese term meaning “continuous improvement”, can be invaluable.

By regularly challenging the inventory status quo and striving for incremental improvements, businesses can maintain a competitive edge, respond swiftly to challenges, and ensure that the inventory strategy remains relevant and efficient.

Remember, the realm of inventory planning is both an art and a science.

These best practices act as guiding stars, helping businesses navigate through the murky waters of inventory management, ensuring smoother operations, delighted customers, and healthy bottom lines.

Whether you’re a budding ecommerce store or a retail behemoth, these practices are integral to mastering the inventory game.

Inventory and warehouse management savings calculator

Uncover the cost of your mis-ships, out of stocks and lack of labor efficiency with our inventory management savings calculator.

Case studies and success stories

TooTonic: A Leap Towards Significant Growth

Background: ecommerce platform, TooTonic, was in search of an efficient way to manage its expanding inventory needs and warehouse operations. As the company grew, the demand for better inventory management and planning became pressing, leading to the integration of Linnworks.

Challenges: as a rapidly growing business, TooTonic experienced challenges in inventory tracking, leading to inefficiencies and inaccuracies.

Manual processes made it challenging to get a real-time view of inventory levels across multiple locations and sales channels.

Scaling operations without compromising on service quality was becoming a considerable challenge.

How Linnworks helped: Linnworks’ automated, inventory software and warehouse management system streamlined TooTonic’s operations, enhancing their productivity.

The central dashboard allowed for a real-time view of inventory, ensuring that inventory levels were always optimized.

The automation reduced the chances of overstocking or stockouts, driving more accurate future inventory and sales forecasts.

Outcome: post-integration with Linnworks, TooTonic witnessed a significant uptick in their growth. The enhanced visibility and automation allowed them to serve their customers better, minimize errors, and operate more efficiently.

Wholefoods: transforming and scaling warehouse management with Linnworks automation

Background: Wholefoods – not to be confused with the U.S. grocery chain – is a UK-based online retailer offering a diverse range of health food, supplements, and organic products.

With a growing customer base and expansion on the horizon, the company needed a sophisticated, yet agile, solution for managing its inventory and warehouse operations.

Challenges: As the company branched out into various sales channels, the manual methods of inventory tracking and order processing became time-consuming and error-prone – it needed to plan its inventory better.

Wholefoods experienced a growing backlog of orders, leading to delayed deliveries and potential customer dissatisfaction.

The increasing product range, combined with multiple sales channels, posed a challenge for real-time inventory management and stock-level maintenance.

How Linnworks helped: Linnworks provided a comprehensive automation solution, directly addressing the bottlenecks Wholefoods was facing in their warehouse management.

The system facilitated real-time inventory tracking across all sales channels, thus reducing discrepancies and overstocking issues.

By automating order processing, Wholefoods managed to drastically reduce its backlog and enhance delivery times. The Linnworks system also enabled seamless management of the vast number of SKUs, ensuring optimal stock levels in real time.

Outcome: with Linnworks’ assistance, Wholefoods transformed its warehouse operations, enabling the company to scale effectively and efficiently.

The real-time tracking and automated order processing system led to improved customer satisfaction, timely deliveries, and a notable growth in sales, all thanks to greater inventory planning. Furthermore, the company could focus on expanding its product range and exploring new market opportunities, knowing that inventory control and warehouse operations were in competent hands.

Wholefoods’ journey with Linnworks showcases the platform’s capabilities in streamlining warehouse and inventory management, especially for businesses looking to scale.

The success story underscores the transformative power of Linnworks in facilitating growth and optimizing operations.

Elevate your inventory planning with Linnworks

Effective inventory planning is an indispensable aspect of modern retail, influencing both operational efficiency and customer satisfaction.

We’ve journeyed through the intricacies of inventory challenges, dissected effective strategies, and dived deep into best practices. We’ve also highlighted the importance of technology, with tools like Linnworks leading the charge in simplifying and optimizing inventory management. Real-world examples, like TooTonic and Wholefoods, stand testament to the transformational power of tools like Linnworks.

As we pivot to the future, integrating robust and accurate inventory planning with tools isn’t just an option; it’s an imperative.

If you’re inspired to elevate your business operations, we invite you to explore Linnworks firsthand. Embark on a 3-minute, self-guided product tour and discover how the platform can be your catalyst for growth and seamless inventory planning.

FAQ

Effective inventory management is the process of maintaining optimal inventory levels to meet customer order demand without overstocking or stockouts. It combines accurate inventory data, inventory visibility across channels, and smart inventory management methods to balance inventory cost, cash flow, and order fulfillment performance. For ecommerce businesses, effective inventory management directly impacts customer satisfaction and supply chain efficiency.

Inventory planning helps reduce inventory cost by ensuring you only stock what you need, when you need it. Using inventory optimization techniques such as demand forecasting, reorder point calculations, and economic order quantity (EOQ), inventory planners can minimize excess inventory, reduce holding costs, and avoid costly emergency reorders. Better inventory planning methods lead to healthier margins and stronger cash flow.

Accurate demand forecasting allows businesses to anticipate customer order volume based on historical inventory data, demand patterns, seasonality, and market trends. Without accurate demand forecasting, retailers risk stockouts, delayed order fulfillment, or overstocked inventory. Strong demand forecast models are foundational to inventory optimization and long-term supply chain planning.

Inventory visibility gives retailers real-time insight into inventory levels across all locations and sales channels. This visibility enables faster decision-making, smoother order fulfillment, and improved supply chain efficiency. With centralized inventory data, inventory planners can respond quickly to changes in demand patterns and prevent disruptions that negatively impact customer experience.

Common inventory planning methods include demand forecasting, safety stock calculation, reorder point planning, ABC inventory analysis, and EOQ modeling. These inventory management methods help businesses prioritize high-impact SKUs, maintain optimal inventory levels, and align inventory planning with broader supply chain planning goals.

When inventory planning is done correctly, products are available when customers place an order, leading to faster order fulfillment and fewer backorders or cancellations. By aligning inventory optimization strategies with accurate demand forecasting and inventory visibility, ecommerce businesses can meet customer expectations, improve delivery times, and build long-term customer loyalty.