The complete guide to ecommerce inventory management for growing ecommerce retailers (2025)

Inventory distortion is one of the biggest barriers to retail growth. Too much stock, too little stock, and poor ecommerce inventory management can tie up funds that you need to grow your business.

Every product in your warehouse, for instance, is tied-up capital. Manage inventory well, and it drives growth. Manage it poorly, and it drains cash flow.

The simple fact is that 69% of online shoppers are already more than willing to abandon their carts before they ever hit “buy.” Poor ecommerce inventory management only serves to push away customers and drive them to your competitors.

As your business grows, this stuff gets complicated fast—you’ve got multiple channels, maybe multiple locations, and suddenly what used to be manageable becomes a complete nightmare.

Businesses that are getting ahead are building operations that adapt to whatever the market throws at them while keeping customers happy.

This guide is going to show you exactly how to do that. We’ll cover the ecommerce inventory management strategies that actually work, the tech that’s changing everything, and give you a roadmap you can actually follow.

Linnworks demo: how to master inventory management

Master inventory management with Linnworks. Centralize stock and automate updates across all your sales channels effortlessly.

Part 1: Foundation – understanding modern inventory management systems

What is modern ecommerce inventory management?

Forget spreadsheets and sticky notes. Modern ecommerce inventory management is all about automation and real-time updates.

With modern inventory management, retailers see better order fulfillment, leading to happier customers and better reviews. These systems offer real-time tracking and predict your needs before you do.

Here’s what you should expect from a modern system:

- Inventory control: Real-time tracking with alerts before you run out of stuff

- Smart purchasing: Tools that predict what you’ll need (and when)

- Advanced forecasting: Systems that look at your sales history, seasonality, and market trends

- Automated fulfillment: Pick, pack, and ship workflows that run themselves

- Predictive analytics: Data that tells you what’s coming next

Choosing the right software: don’t mess this up

Choosing the right ecommerce inventory management software is crucial—it can make or break your business.

Here’s what you absolutely need:

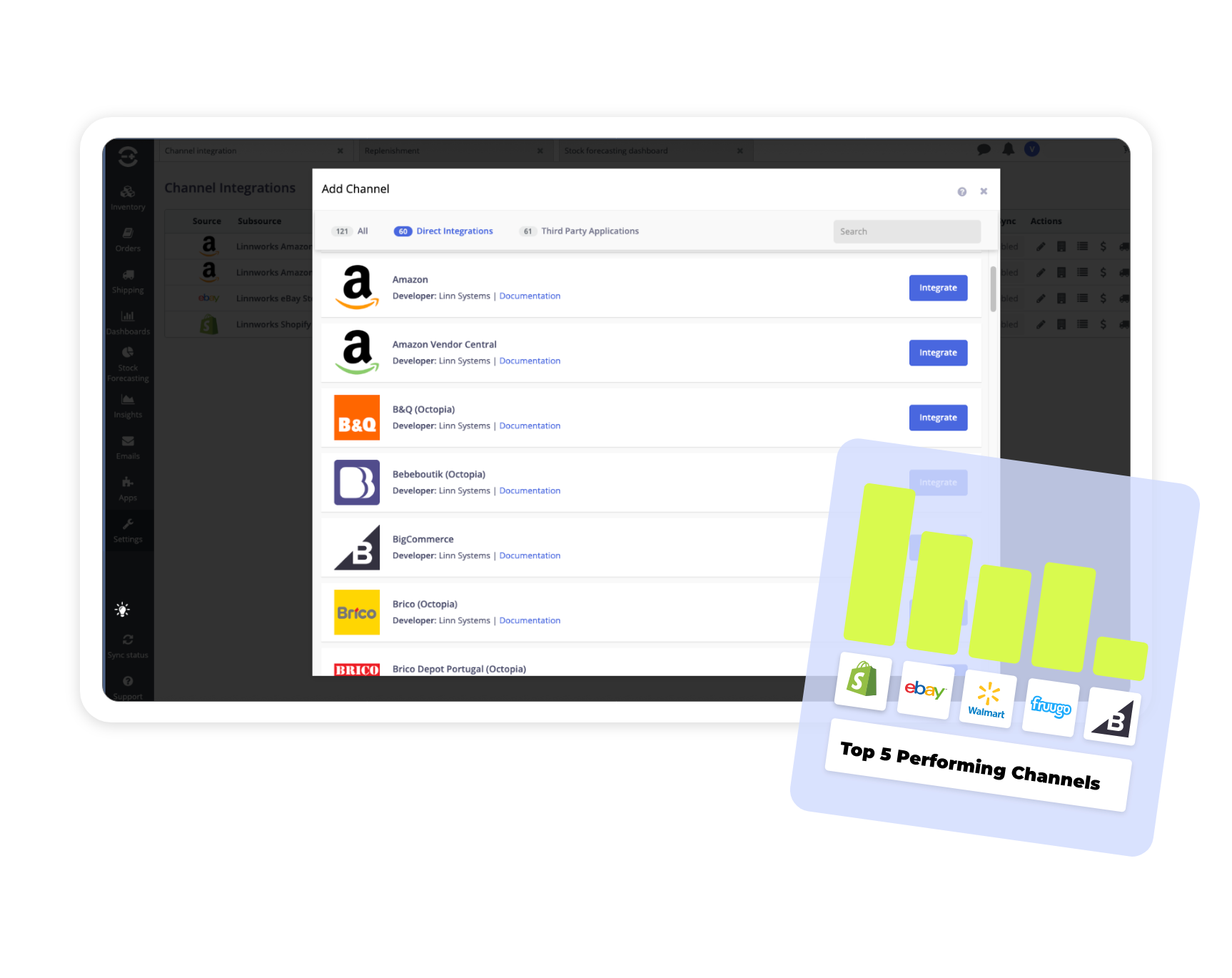

Multichannel integration isn’t optional anymore. Your system needs to sync inventory across your Shopify store, Amazon, Walmart, physical stores—wherever you’re selling. This is where multichannel inventory management becomes essential, ensuring that stock levels update consistently no matter where you sell. If you’re doing omnichannel (and you should be), you need systems that can handle the complexity.

Real-time tracking means knowing where everything is, all the time. Modern systems use RFID tags, barcode scanning, and IoT sensors to give you up-to-the-minute updates. No more “I think we have five of those in the back.”

AI-powered analytics is where things get really interesting. These systems predict what’s going to happen. We’re talking about analyzing massive amounts of data to forecast demand with scary accuracy.

Scalability is crucial because hopefully your business is going to grow. Your system needs to handle more SKUs, more orders, and more locations without falling apart. Companies using data analytics for inventory decisions see better cost reductions across the board.

Part 2: Strategic approaches to inventory control

Bulk vs. lean vs. hybrid: pick your strategy

The old-school approach was simple: either buy a ton of stuff (bulk) or buy just what you need (lean). But that’s way too simplistic for today’s market.

Bulk inventory still makes sense sometimes. If you’ve got products with steady, high demand, or you know prices are going up, or you’re prepping for a busy season—yeah, buy in bulk. You’ll get better unit costs and protect yourself against supply chain hiccups.

Lean inventory (Just-in-Time) is all about efficiency in ecommerce inventory management. You’re only storing what you absolutely need, which saves on storage costs and keeps your cash from being tied up in inventory. But here’s the catch—you need suppliers you can absolutely rely on, and your demand forecasting better be spot-on.

Hybrid is where it’s at for most growing businesses. Run lean during slow periods to optimize cash flow, then switch to bulk buying before busy seasons. Use AI to figure out exactly when to make that switch.

Calculating optimal inventory levels: the math that matters

Economic Order Quantity (EOQ) 2.0 isn’t the old EOQ formula. Modern versions factor in real-time demand changes, supplier lead times that actually vary, seasonal adjustments, and demand from multiple channels.

The new Reorder Point formula looks like this:

ROP = (Average Daily Usage × Average Lead Time) + Dynamic Safety Stock + Channel-Specific Buffer.

AI-enhanced safety stock is a game-changer. Businesses using machine learning for demand forecasting hit higher accuracy compared to those with manual methods. These systems consider how demand varies across channels, how reliable your suppliers actually are, seasonal patterns, and market volatility.

State of your commerce quiz

How do your ecommerce operations stack up? Take our quiz to see where you stand and get actionable next steps to improve your workflows.

Part 3: Operational excellence – getting the details right

Next-generation auditing: beyond counting stuff

Human error remains a major challenge in warehouse operations, leading to mis-picks, wrong counts, and costly mistakes. Modern auditing prevents problems before they happen.

The enhanced audit process:

- Automated Counting: RFID and IoT sensors do the counting for you

- Real-Time Comparison: AI flags problems immediately

- Pattern Recognition: Machine learning spots recurring issues

- Root Cause Analysis: Figure out why problems keep happening

- Automated Fixes: Smart systems fix approved issues automatically

- Prevention: AI suggests improvements to stop future problems

Building accuracy into your culture means making it fun, using mobile devices for real-time updates, and having visual systems that show status at a glance.

Multi-location and omnichannel: the complex stuff

Once you’re selling across multiple channels, ecommerce inventory management gets tricky fast. You need to coordinate between stores, distribution centers, and online operations while keeping prices and promotions consistent everywhere.

Location strategy comes down to three options: centralized (simple to manage but expensive to ship), distributed (cheaper shipping but complex operations), or hybrid hub-and-spoke (best of both worlds with regional centers).

Real-time sync isn’t negotiable. Your inventory system needs to be like the nervous system of your business—instantly updating stock levels across all channels when sales happen. Otherwise, you’ll oversell and have very unhappy customers.

Why Linnworks is the smarter choice for ecommerce growth

Unlock the secrets of ecommerce growth with Linnworks. Simplify operations and scale your business efficiently.

Part 4: Advanced strategies for serious growth

Automation and AI: not optional anymore

Most ecommerce companies are investing in inventory automation. Why? Because it’s a practical way to manage growth.

Key automation opportunities:

- Smart Purchase Orders: Automatic reordering when you hit reorder points

- Intelligent Routing: System picks the best fulfillment location

- Dynamic Allocation: Real-time optimization based on demand

- Predictive Maintenance: Sensors that predict equipment failures

AI forecasting offers advanced capabilities by analyzing factors such as sales history, seasonality, market trends, weather, and even social media sentiment to accurately predict demand. These insights sit at the core of effective AI inventory management, where data-driven systems continually refine predictions as new information comes in.

Ecommerce automation 101

Discover how ecommerce automation can free up your team and eliminate daily chaos in your online business.

Scaling and going global

Preparing for scale means choosing cloud systems that grow automatically, designing warehouses that can expand, building vendor relationships that scale, and standardizing processes everywhere—all core aspects of modern ecommerce inventory management.

International expansion adds complexity to ecommerce inventory management: longer lead times, customs delays, regional compliance requirements, localized products, and local fulfillment partners.

Supply chain resilience is critical. Diversify suppliers, keep safety stock, plan for contingencies, and use blockchain for transparency.

Part 5: What’s coming next

Cutting-edge tech that’s actually useful

Blockchain creates permanent, tamper-proof records of every product movement—an innovation shaping ecommerce inventory management in 2025. You get complete transparency, authenticity verification, and streamlined compliance.

IoT and smart sensors mean every item can tell you where it is, what condition it’s in, and whether it’s being stored properly, advancing real-time ecommerce inventory management.

Robotics through AGVs and AMRs improve picking accuracy, increase throughput, cut labor costs, and make warehouses safer—raising the bar for ecommerce inventory management operations.

Sustainability and returns

Reverse logistics is getting more important as ecommerce grows. Efficient returns processing cuts costs, makes customers happier, reduces environmental impact, and creates resale opportunities.

Sustainable practices include optimizing packaging, implementing circular economy principles, using analytics to minimize overproduction, and partnering with sustainable suppliers.

Live demo: mastering returns management

Discover how Linnworks streamlines returns management for eCommerce.

Part 6: Your implementation roadmap

Assess where you are

Still using Excel for ecommerce inventory management? Don’t worry—we’ll help you out. Begin by conducting a thorough gap analysis of your current tech, process efficiency, staff capabilities, and how everything connects (or doesn’t).

Gap analysis should cover:

- Software upgrades or replacements

- Process standardization

- Staff training needs

- Technology integration opportunities

Phase your implementation: Foundation (core systems), Optimization (process refinement), Advanced (AI integration), Scale (multi-location analytics).

Managing change and measuring success

Get buy-in by communicating why this matters, sharing success stories, involving stakeholders in decisions, and setting clear metrics.

Train everyone with role-specific programs covering executive dashboards, warehouse operations, purchasing workflows, and customer service.

Monitor performance by tracking inventory accuracy, turnover rates, fulfillment speed, cost reduction, and customer satisfaction.

Optimize inventory control and order management with Linnworks

Navigating the complexities of ecommerce inventory management is a defining challenge for ecommerce leaders—but the right technology can turn operational headaches into opportunities for growth.

Throughout this guide, we’ve unpacked proven techniques, from strategic order methods like FIFO, LIFO, and EOQ, to the power of cycle counting and ABC analysis, all designed to maximize efficiency, profitability, and customer experience.

Yet, even the best strategies rely on effective execution. That’s where a robust inventory management system like Linnworks puts you ahead of the competition.

How can Linnworks elevate your ecommerce inventory management?

- Centralized, real-time inventory tracking: Gain full visibility and control by consolidating inventory data from every sales channel and warehouse into one intuitive dashboard. Make informed decisions and prevent costly stockouts or overstock scenarios with up-to-the-minute information.

- Automated order management: Streamline fulfillment with automation. Linnworks updates stock levels across all platforms the moment a sale is made, triggers reorder alerts, and minimizes manual errors. This frees your team to focus on strategic initiatives that drive growth, while customers benefit from accurate, fast shipping.

- Advanced forecasting and demand planning: Move beyond guesswork. Linnworks analyzes historical sales, seasonal trends, and real-time data so you can anticipate demand, replenish products efficiently, and reduce excess inventory. Turn forecasting into a competitive advantage.

Successful ecommerce inventory management is about using the right tools to unlock your organization’s potential. Linnworks empowers you to centralize, automate, and optimize every aspect of your inventory and order operations.

Are you ready to turn your inventory from a challenge into a strategic advantage?

Request a demo today and experience firsthand how streamlined management can fuel your next phase of ecommerce growth.