Inventory Reconciliation: 6-Step Process to Stop Stock Shrink & Protect Profit

,

Are you constantly fighting fires caused by inaccurate stock levels?

If your recorded inventory numbers don’t match the actual inventory item count on your shelves, this discrepancy can derail your entire operation. Lost sales, frustrated customers, and unexplained losses are enough to put your business in the red—yet regular inventory reconciliation can bring those numbers back in line.

The good news is that you don’t have to implement a complex, time-consuming overhaul; all it takes is a clear plan to fix your balance sheet.

In this blog we’ll give you a straightforward framework built on proven inventory reconciliation best practices. Read on to learn:

- A clear, 6-step process to take you from initial count to final analysis.

- Smart methods—including the ABC inventory control system—to help you prioritize high-value items and save time.

- Actionable tips to diagnose the root causes of discrepancies and prevent them from happening again.

Let’s dive in and get your inventory under control.

Inventory and Warehouse Management Savings Calculator

Uncover the cost of your mis-ships, out of stocks and lack of labor efficiency with our inventory management savings calculator.

6 Core Steps to Better Inventory Reconciliation

What is inventory reconciliation?

In a nutshell, inventory reconciliation is the process of making sure the numbers in your system match the number of products you physically have on your shelves. It sounds simple, but as your business grows, it’s rarely easy to implement—especially when you must keep accurate inventory records across multiple channels.

When you first started, managing a small inventory for one platform was straightforward. But what happens when you add a second location, a third-party warehouse, and start selling across multiple ecommerce platforms?

Your inventory balance is now constantly changing across different systems and locations. The moving parts get out of sync, and suddenly you’re dealing with issues like:

- Finding discrepancies but having no idea if they’re from simple miscounts, receiving errors, or shrinkage.

- Showing stock on one sales channel that doesn’t actually exist in the warehouse.

- Wasting valuable time and manpower on what feels like a never-ending cycle of counting.

To cut through that complexity, you need a reliable process. Here’s the 6-step framework and best inventory management practices that successful businesses use to establish control.

➡️ The 6-Step Inventory Reconciliation Framework

- Count The Products: Conduct a physical count of the inventory you have on hand, using either a full count or cycle counting method.

- Check Your Records: Ensure all your records—from supplier invoices to sales data in your inventory control systems—are accurate and up to date.

- Examine Discrepancies: Compare your physical count to your records to create a clear list of every mismatch.

- Chase Down Discrepancies: Investigate the gaps you’ve found, focusing first on high-value items or recurring problems to find the root cause.

- Reconcile Your Records: Adjust your official inventory records to match the physical reality, making notes of any changes for financial reporting.

- Analyze Your Results: Compare the results of your current reconciliation with past ones to identify trends, patterns, and areas for process improvement.

That 6-step framework is your roadmap to properly reconcile inventory. But as with any business process, real success lies in the execution. After all, knowing the steps is one thing; implementing them effectively is another.

In the following sections, we’ll walk through each step in detail, covering the best practices to properly sync your inventory data and common pitfalls to look out for.

Let’s begin with the foundation of any reconciliation: the physical count.

📦 Step 1: Count Your Physical Inventory

This is the foundation of your entire reconciliation process. The goal is simple: to get a precise, physical count of the products you have on hand to compare against your recorded inventory levels.

How you get that count can vary. Generally, businesses choose between two primary methods: a full inventory count or cycle counting.

Method A: The Full Inventory Count

A full inventory count is exactly what it sounds like: your team, or an outside company, counts every single physical item in your facility in one go. This can be done with anything from a clipboard to barcode scanners or RFID technology.

- The Upside: This approach provides a complete and highly accurate snapshot of all your stock at that specific moment in time.

- The Downside: The biggest drawback is that this kind of comprehensive count often requires you to shut down your operations while it’s being conducted. Depending on the size of your warehouse, that downtime can be costly. Furthermore, the sheer volume of counting everything at once can be a daunting task that may lead to errors.

Method B: Cycle Counting (A More Flexible Approach)

Instead of counting everything at once, cycle counting involves counting specific, smaller portions of your inventory on a rotating, daily basis. Over a set period, you end up counting your entire inventory, just in manageable pieces.

- The Upside: The main advantage is that cycle counts can be conducted without disrupting the daily operation of your business. These smaller counts are less stressful for your team and, because they cover a limited area, there’s less chance of error.

- The Downside: Because the data is collected over time rather than in one session, it can be subject to discrepancies as time passes. To solve for this, many businesses will run their regular cycle counts but still conduct a full inventory periodically to ensure their numbers are as accurate as possible.

No matter which method you choose, the goal of this first step is to get a reliable number for the product you physically have on hand. That data drives the entire reconciliation process, ensuring the inventory levels in your system reflect reality.

📝 Step 2: Check and Verify Your Records

Once you have your physical count, the next step is to ensure the inventory records—and any linked accounting records—are accurate. This means making sure your inventory records, including any inventory control systems, are current with the latest sales and invoice data.

As you compare records for each item, pay close attention to stock and serial numbers to ensure they match. More often than not, discrepancies originate within the records themselves.

Here are the most common issues that undermine regular inventory reconciliation attempts:

- Missing or Misplaced Paperwork: This is one of the most frequent causes of inventory discrepancies. All inventory-related paperwork should be filed in a single, accessible location. Using an inventory management software can make this much easier to manage.

- Human Error: Simple mistakes happen, especially when it comes to tracking inventory. One of the most common types of human error involves math. If you find a problem, save yourself a headache and check the math first.

- Unlisted Items: Sometimes, inventory ends up in your warehouse without being properly checked in and recorded. If your count reveals unlisted items, you’ll need to research the paperwork and add them to your official inventory for future counts.

- Supplier Fraud: While rare, supplier fraud is a real issue. This is why having accurate and diligent inventory receiving practices is so important—it’s easier to catch fraud upon arrival than during a reconciliation.

- Backflushing: If you use a perpetual inventory system, you might use a practice called backflushing, where the system automatically accounts for materials consumed during production. For example, when a car rolls off the assembly line, four wheels are automatically “consumed” from inventory. If you use this method, you must account for it during your reconciliation.

- Shrink: This refers to unaccounted-for inventory loss, and it affects every business. If you’ve checked all the other steps and numbers are still off, you may have a shrink problem due to customer or employee theft.

By systematically checking for these common issues, you can clean up your records, making the comparison in the next step much more effective.

🔍 Step 3: Examine and Prioritize Discrepancies

Now that you have a clean physical count and verified records, it’s time to compare them. As you go through the results of your inventory audit, you will likely uncover discrepancies.

This is a normal occurrence, so don’t despair if you find them.

The real challenge isn’t just finding these gaps, but deciding which ones warrant your limited time and resources.

Treat discrepancies the same way finance teams approach bank reconciliation or balance-sheet reconciliation—focus first on items that pose the greatest financial risk. A missing box of low-cost screws doesn’t have the same business impact as a missing high-end electronic device.

This is where you need to prioritize. Instead of treating all inventory equally, successful managers use a method known as the ABC Inventory Control System.

How to Prioritize: The ABC Inventory Control System

This system divides your inventory into three categories based on value, not volume.

- Category A: High-Value Inventory. These are your most critical products. They typically represent only 15-25% of your total items but account for a large portion of your sales and profitability. Any loss or shrinkage here is a much bigger concern and has a greater impact on your operations.

- Category B: Moderate-Value Inventory. This category includes items that are less critical than Category A but more valuable than Category C.

- Category C: Low-Value Inventory. These are your least valuable items.

By categorizing your stock this way, you create a clear action plan. The discrepancies you found for your Category A items should be your absolute top priority for investigation in the next step.

For low-value items in Category C, you may decide that the time and expense to track down the cause of the loss isn’t worth it.

🕵🏻 Step 4: Investigate High-Priority Discrepancies

With your prioritized list from Step 3, you can now conduct a focused investigation instead of trying to solve every single mystery. Your goal is to chase down the root cause of the discrepancies for your high-value (Category A) items.

Start by reviewing systems and processes (similar to an account reconciliation exercise) before focusing on individuals.

First, go through your sales records again to identify the possibility that some sales were not recorded accurately. If you cannot find any missing sales receipts, the issue may be lost or misplaced merchandise, or potentially theft or fraud.

Often, discrepancies happen because steps get missed in the recording process, whether in the warehouse, on the retail floor, or on eCommerce platforms. It’s helpful to interview employees responsible for each step to determine if there’s a simple explanation for the discrepancy that can be easily addressed.

It’s up to you to determine the acceptable level of shrinkage in your business. For some discrepancies, especially for lower-value items, it may be more time-consuming and expensive to track down the cause of the loss than to simply move on. The key is to resolve what you can without letting the investigation process become so bogged down that it stretches into your next inventory count.

🗂️ Step 5: Reconcile and Adjust Your Records

This step is about making the official change. Whether you were able to track down the cause of a discrepancy or not, you must have an accurate inventory count in your system.

Adjust your inventory records to match the physical count you took in Step 1.

Crucially, don’t just change the numbers. Make a detailed note of the changes you make. This documentation is essential for updated financial reporting and for any necessary write-offs your business will have to make.

Even if you have to accept that some issues can’t be explained, you need to reconcile your books to the physical reality and move forward. These unresolved discrepancies will be important in the final step of our process.

📊 Step 6: Analyze Results to Prevent Future Issues

Your reconciliation isn’t truly finished until you use the data you’ve gathered to make the next one easier. As a final step, compare the results of your current inventory reconciliation with previous ones.

This comparison is crucial because it helps you surface trends, patterns, and areas that need further examination. Link these insights back to your general-ledger or financial-statement reconciliation routines to ensure operational and accounting data stay in sync. It’s how you move from constantly fixing problems to preventing them from happening in the first place.

Here’s what to look for:

- Recurring Problems: Are the same items always showing discrepancies? Being aware of these unexplained issues allows you to better focus on those particular items in the future, which can help you discover the root cause, whether it’s shrink, human error, or a process flaw.

- Growing Shrinkage Rates: If you notice your overall shrinkage rates are starting to grow, it may be a signal that you need to improve your loss prevention strategies.

- Systematic Issues: Analyzing trends can also reveal larger, systematic problems, such as consistently missing shipments from a certain supplier or even potential fraud.

By taking the time for this final analysis, you create a cycle of continuous improvement. The best way to maintain this is to utilize an end-to-end inventory control system that provides greater accuracy and real-time records for review. This turns reconciliation from a periodic headache into a powerful, ongoing business strategy.

Ready to Automate Your Reconciliation and Eliminate Guesswork?

Following this six-step inventory reconciliation process is the fastest way to maintain accurate numbers while preventing manual reconciliation bottlenecks. But performing these steps manually—with clipboards, spreadsheets, and endless data entry—is often the biggest bottleneck. This is where your process can be streamlined with the right tools.

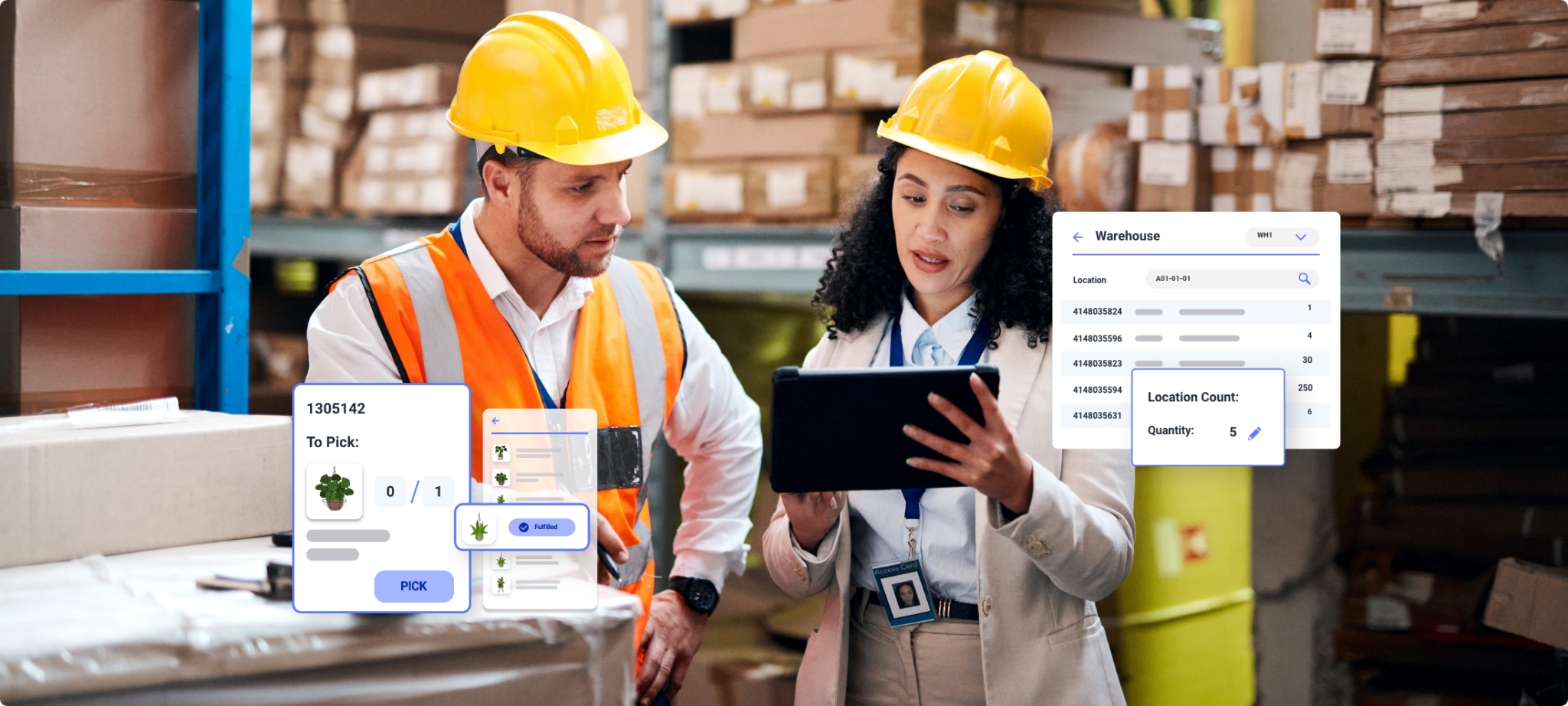

A powerful Inventory and Warehouse Management System like SkuVault Core can help you execute this step faster and with greater accuracy.

Here’s how it helps you achieve that result:

- It tackles manual errors and slow counts. By integrating with tools like barcode scanners, you can eliminate manual data entry, reduce human error, and make your physical counts faster and more reliable.

- It provides a single source of truth. For businesses with multiple platforms and locations that easily get out of sync, the system provides greater accuracy and accountability by tying your POS system, warehousing, and delivery together in an integrated manner.

- It makes analysis easier. Rather than digging through old reports to spot trends as we discussed in Step 6, a centralized system gives you real-time records for review, helping you identify and prevent future issues before they become major problems.

If you are ready to see exactly how this can work for your unique business, request for a personalized demo to see how SkuVault Core can transform your business.